| –

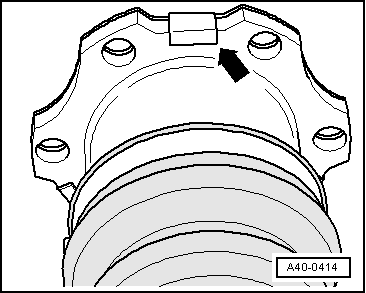

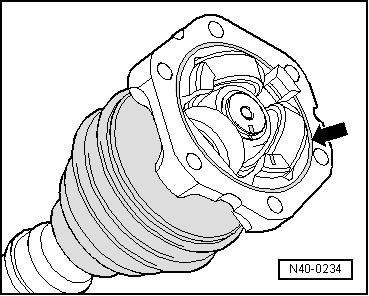

| Insert the tripod onto the half-shaft according to the marks that were made previously and insert it to the limit. |

| –

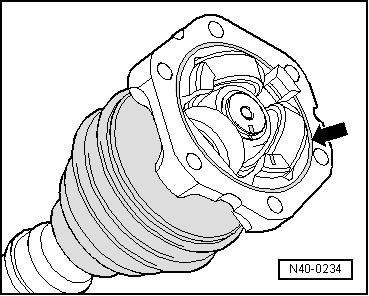

| Insert retaining ring, ensuring that it is seated correctly. |

| –

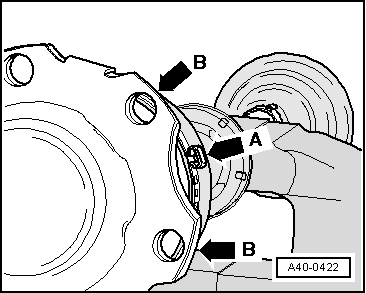

| Slide joint body over rollers and hold. |

| –

| Fill half the specified grease for the half-shafts in the repair kit in the → tripod joint. |

| –

| Put the other half of grease into the rear of the tripod joint from the repair kit. |

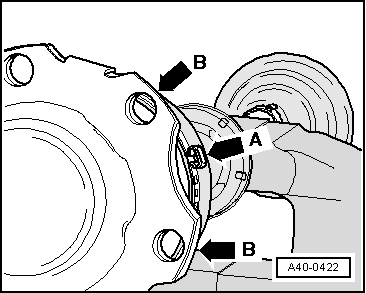

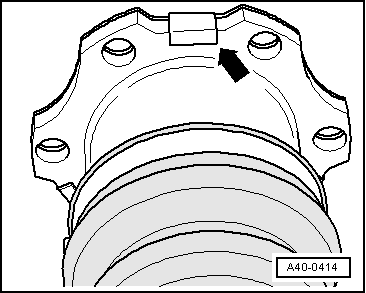

| The edge of the dust guard should insert into the groove on the joint housing. |

| –

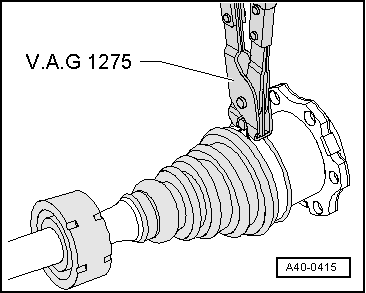

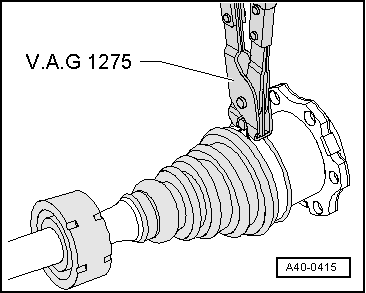

| Remove the complete half shaft from the bench vice and attach it to the joint casing. |

|

|

|

Note

Note

Note

Note