Leon Mk2

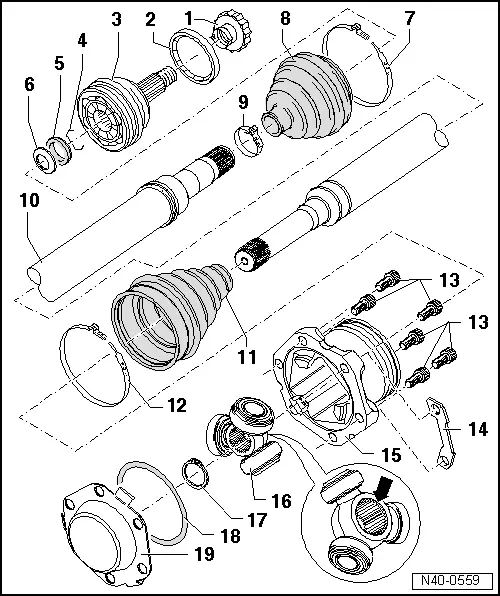

| Drive shaft with → tripod joint - Assembly overview |

| 1 - | Twelve-sided, self-locking nut |

| q | Tightening torque → Chapter |

| q | Replace after each removal |

| q | Black colour for the 13" running gear |

| q | Silver colour for the 14" and 15" running gear |

| q | Remove any corrosion on the thread of the outer joint before the nut is screwed on. |

| 2 - | Centrifugal disc |

| q | Check that it clips into the groove properly |

| 3 - | Outer constant velocity joint |

| q | Always replace completely |

| q | Removing → Fig. |

| q | Installation: insert into the complete half-shaft as far as possible by hitting with a plastic hammer. |

| q | check → Chapter |

| 4 - | Circlip |

| q | Replace after each removal |

| q | Fit into the groove on the complete half-shaft |

| 5 - | Thrust washer |

| q | Installation position → Fig. |

| 6 - | Dished spring |

| q | Installation position → Fig. |

| 7 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 8 - | Dust boot |

| q | Ensure that there is no damage or cracks from friction |

| q | Material: → Hytrel (polyelastomer) |

| 9 - | Clamp |

| q | Replace after each removal |

| q | Tension → Fig. |

| 10 - | Left hand driveshaft |

| q | Allocation: → Parts catalogue |

| 11 - | Dustguard for → tripod joint |

| q | Ensure that there is no damage or cracks from friction |

| 12 - | Clamp |

| q | Replace after each removal |

| q | Tension → Anchor |

| 13 - | Multi-point socket head bolt |

| q | Tightening torque → Anchor |

| q | Replace after each removal |

| 14 - | Locking plate |

| q | only in conjunction with the inner spline head bolt M 8 x 28 |

| q | Allocation: → Parts catalogue |

| 15 - | Joint body |

| 16 - | Triple roller star with rollers |

| The bevel -arrow- should face the driveshaft cog |

| 17 - | Circlip |

| q | Always replace |

| 18 - | O-ring |

| q | Always replace |

| 19 - | Panel |

| q | Always replace |