| –

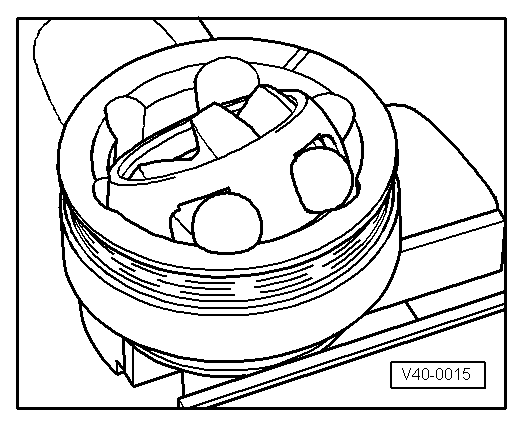

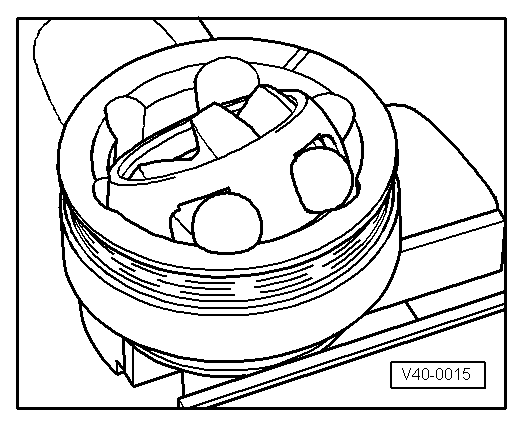

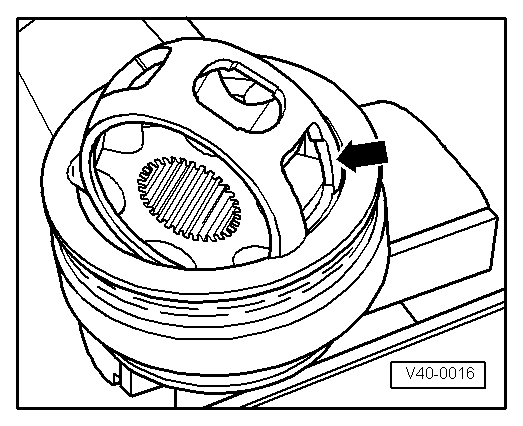

| Fit the hub segment on the rectangular space of the cage. |

| –

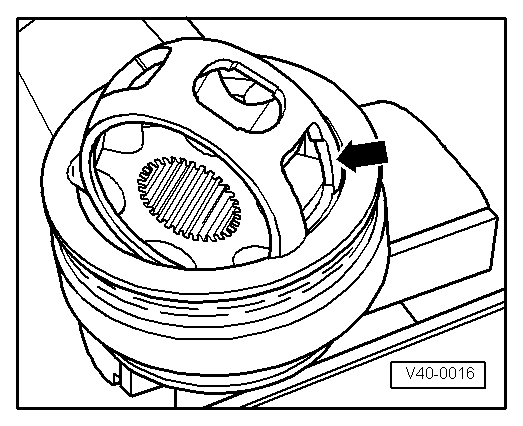

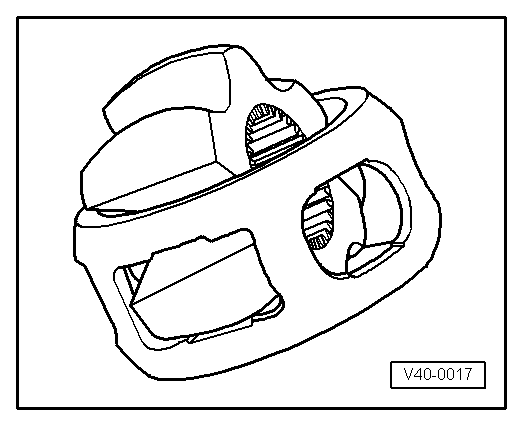

| Remove the hub from the cage. |

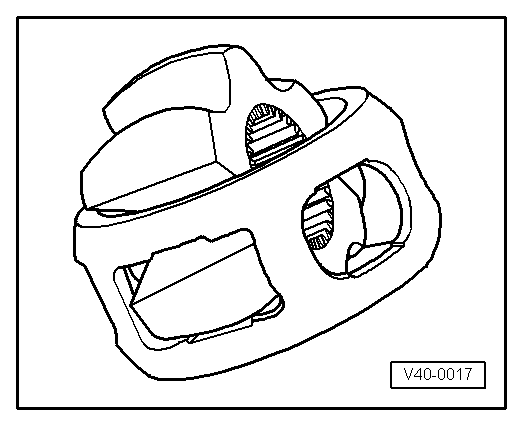

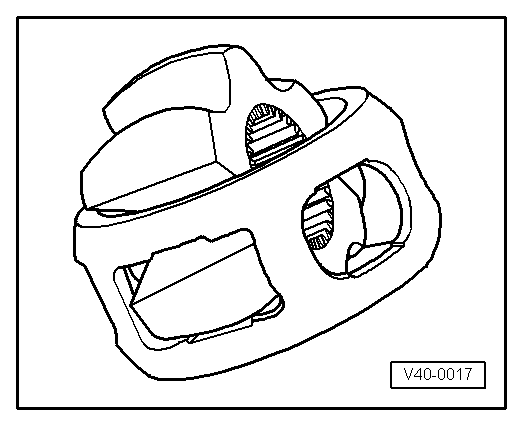

| The 6 ball bearings of each joint belong to a tolerance group. Check the axle rod, the hub, the cage and the ball bearings for scratches (pitting) and tracks from grinding. If the turning play of the joint is excessive, this will manifest itself in the form of banging when the load is inverted, if so, the joint should be replaced. The smooth areas and the tracks on the balls do not imply a need to replace the joint. |

|

|

|