Leon Mk2

| Driveshaft with tripod joint AAR 3300i: repairing |

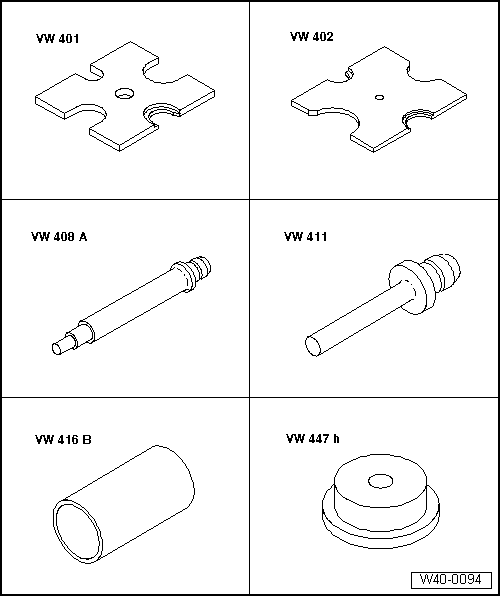

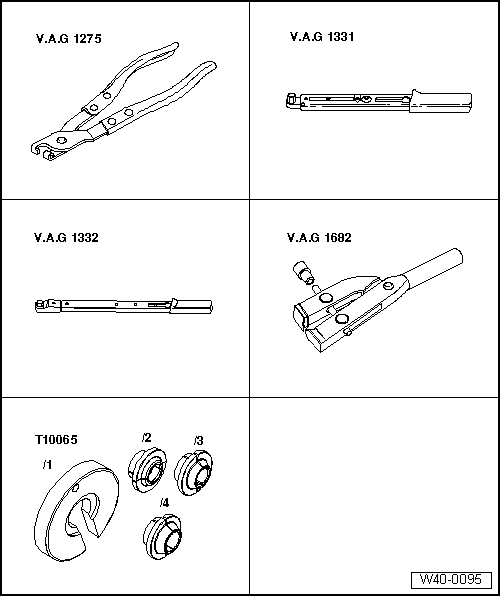

| Special tools and workshop equipment required |

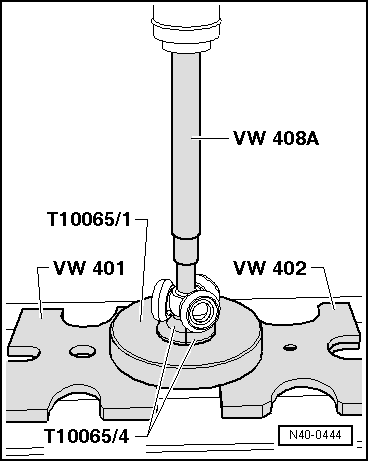

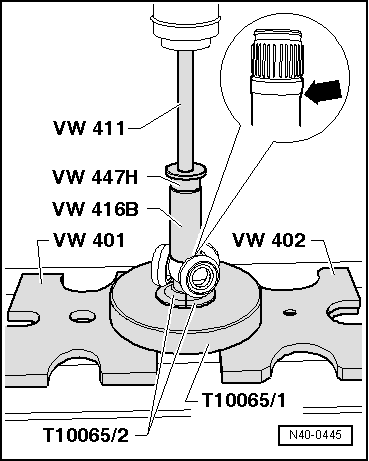

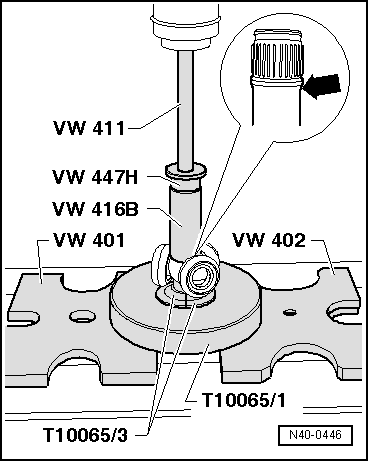

| t | Pressure plate -VW 401- |

| t | Pressure plate -VW 402- |

| t | Terminal crimper -VW 408 A- |

| t | Terminal crimper -VW 411- |

| t | Tubular part -VW 416 B- |

| t | Pressure plate -VW 447 H- |

| t | Pliers -V.A.G 1275- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Pliers -V.A.G 1682- |

| t | Assembly tool -T10065- |

|

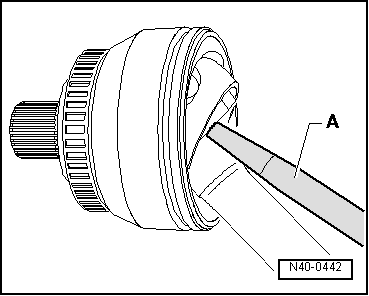

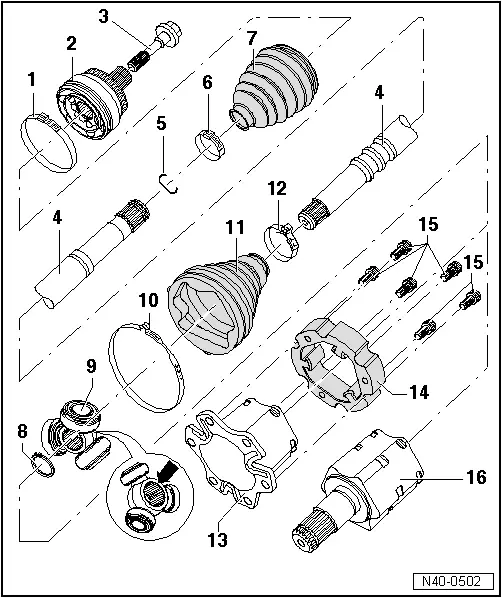

| 1 - | Tightening clip |

| q | Replace |

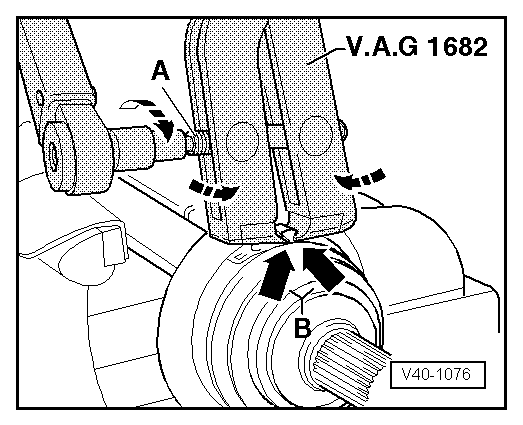

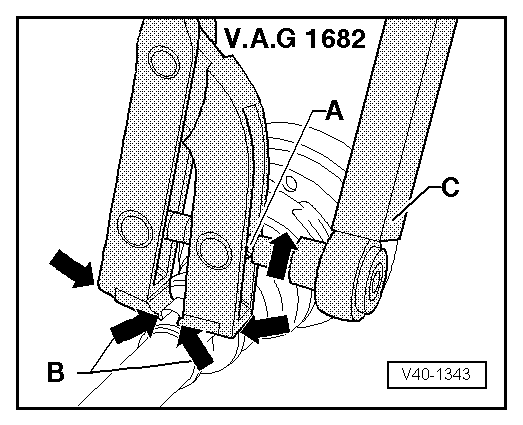

| q | Tighten → Fig. |

| 2 - | Constant velocity exterior joint |

| q | Only replace entirely |

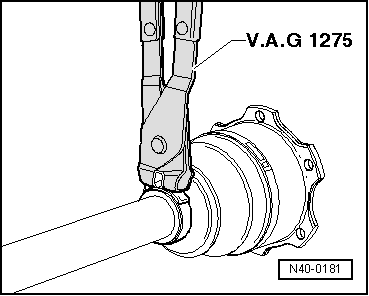

| q | Releasing → Fig. |

| q | Checking → Chapter |

| q | insert into the driveshaft using a plastic hammer, until the compressed circlip is decompressed |

| q | Grease → |

| 3 - | Hexagonal bolt |

| q | 150 Nm, and turn a further 90° |

| q | When tightening and loosening, the vehicle must rest on its wheels |

| q | Replace after each removal |

| 4 - | Driveshaft |

| 5 - | Circlip |

| q | Replace |

| q | Insert in the driveshaft groove |

| 6 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 7 - | Dust guard for constant velocity joint |

| q | Material: Hytrel (polyester elastomer) |

| q | Without ventilation opening |

| q | Check for cracks or wear, and replace if necessary |

| 8 - | Circlip |

| q | Replace |

| 9 - | Tripod and rollers |

| The bevel -arrow- should face the driveshaft cog |

| q | Releasing → Fig. |

| q | Fit the driveshaft with the conical end → Fig. |

| q | Fit the driveshaft with the cylindrical end → Fig. |

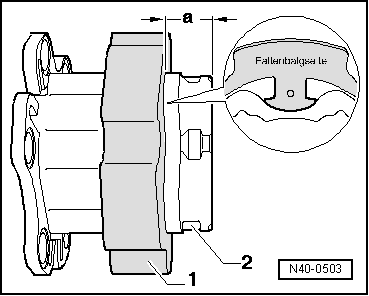

| 10 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 11 - | Dust guard for tripod type joint |

| q | With breather hole |

| q | Ensure that there is no damage or cracks from friction |

| 12 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 13 - | Joint casing |

| 14 - | Counterweight |

| q | Assembly position → Fig. |

| 15 - | Bolt with internal splined head |

| q | First tighten diagonally to 10 Nm |

| q | Tighten completely to 70 Nm |

| q | Replace after each removal |

| 16 - | Flanged shaft for right-hand side tripod joint |

| q | Only vehicles with automatic gearbox and 150 kW engine |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|