Leon Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||||

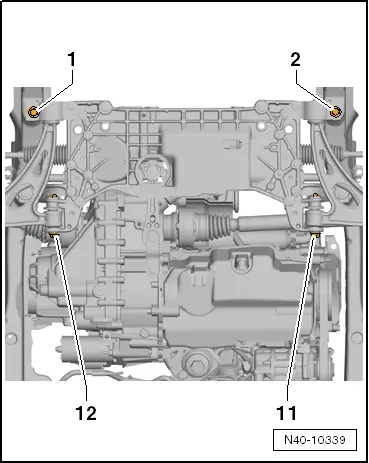

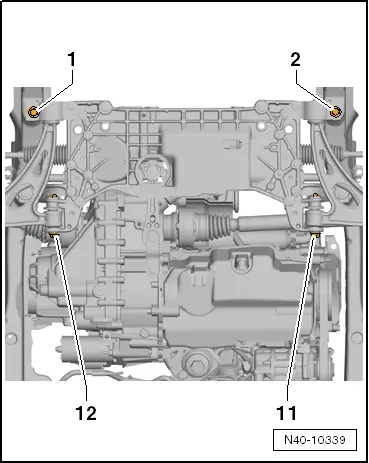

Mounting bracket to body

| 70 Nm + 180° | ||||

Mounting bracket to subframe

| 50 Nm + 90° | ||||

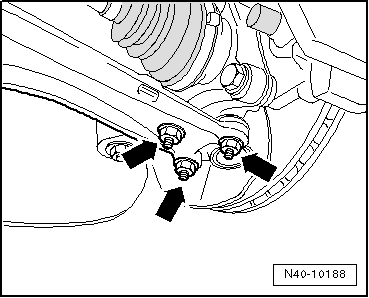

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

Suspension link to subframe

| 70 Nm + 180° | ||||

| Coupling rod for front left vehicle level sender -G78- to suspension link | 9 Nm |

Caution

Caution