| –

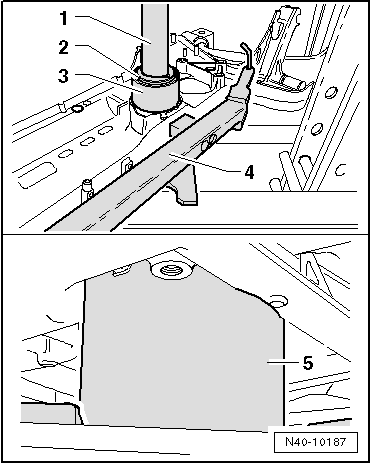

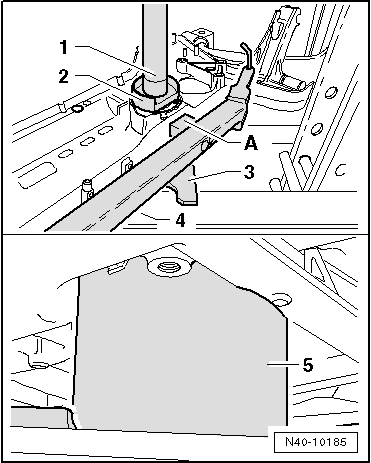

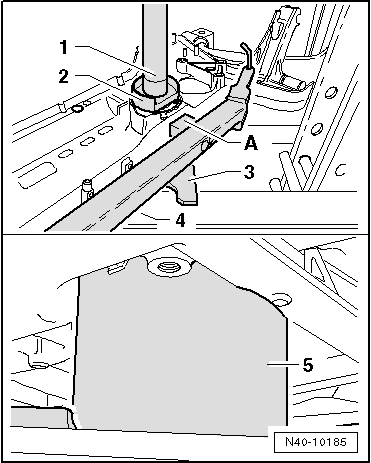

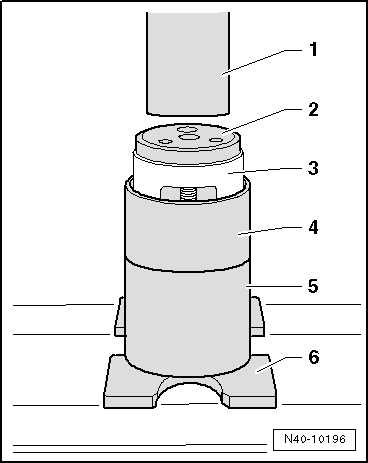

| Attach assembly tool -T10267--4- to subframe. Secure retaining pins of tool with locking pins. |

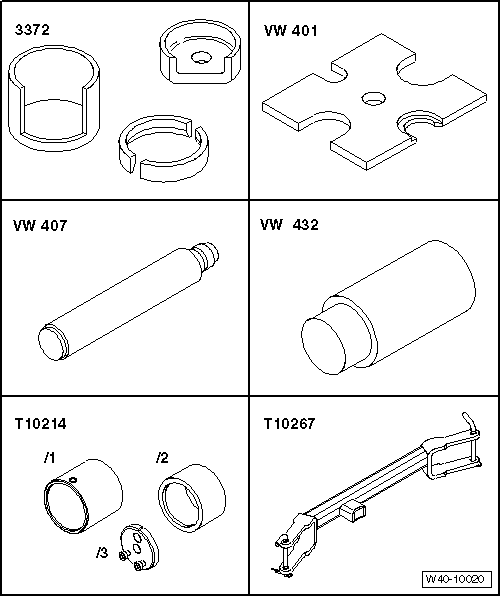

| 2 - | Thrust piece -3372/1- |

| 3 - | Tightening plate -VW 401- |

| –

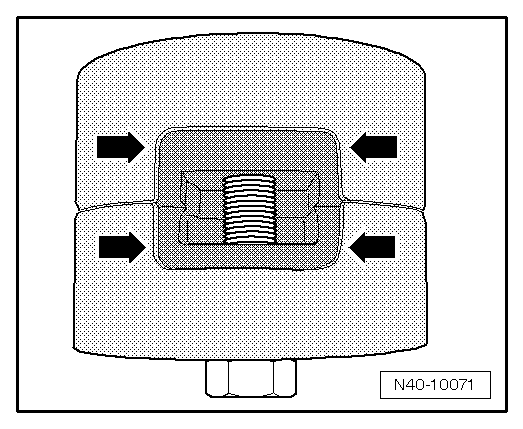

| Press out both bonded rubber bushes together as shown. |

Note | t

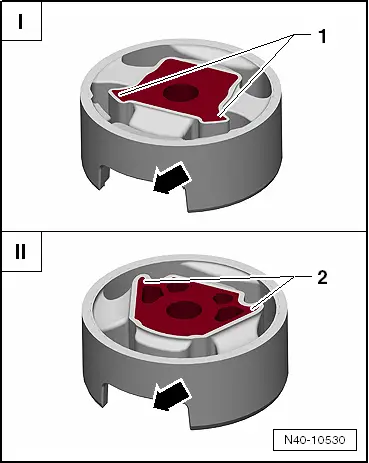

| Flattened side of thrust piece -3372/1- must face towards insert -A- of traverse -T10267-, as otherwise insert may be damaged. |

| t

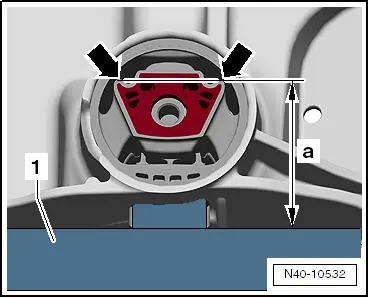

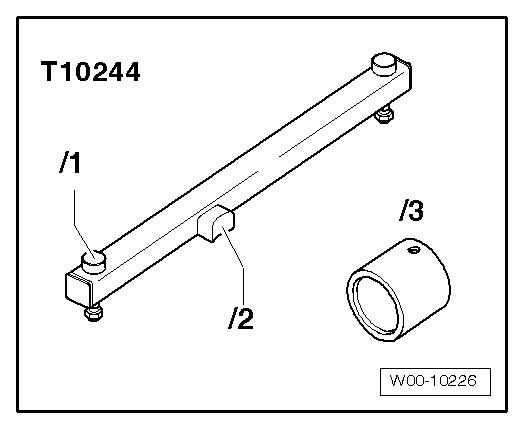

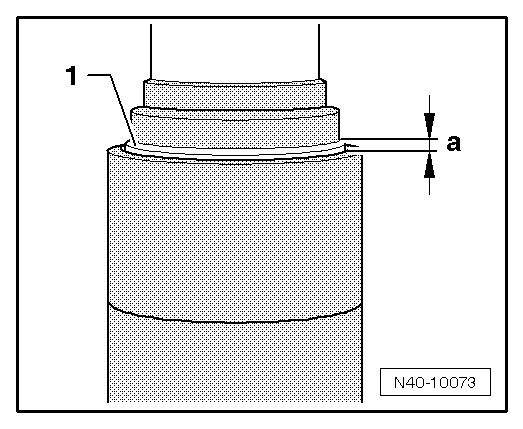

| The tube -T10244/3- has two different internal diameters. The subframe must lie against the larger internal diameter of the tube -T10244/3-. |

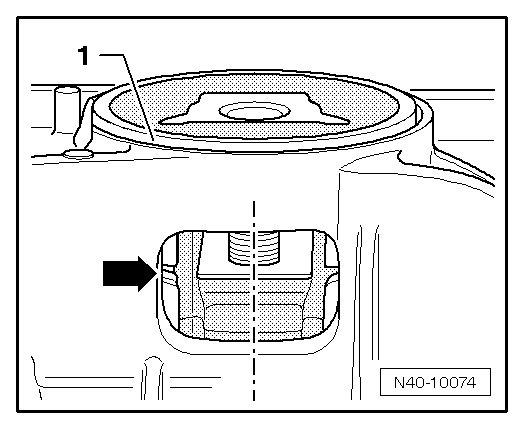

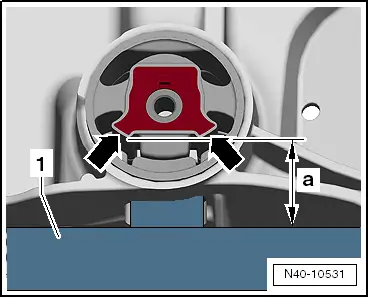

| Press out bonded rubber bush. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note