Leon Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

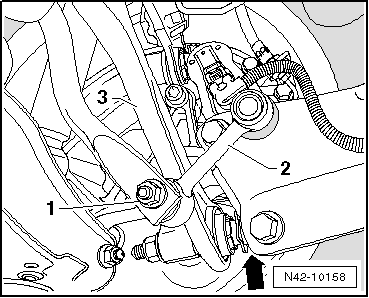

| Specified torques |

| Component | Tightening torque | ||||

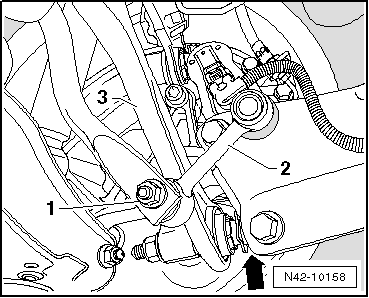

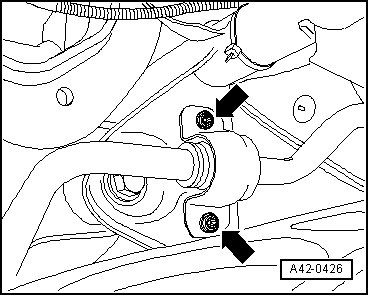

Track rod to wheel bearing housing

| 130 Nm + 90° | ||||

Track rod to subframe

| 90 Nm + 90° | ||||

Anti-roll bar to subframe

| 25 Nm + 45° | ||||

Anti-roll bar to coupling rod

| 40 Nm |