Leon Mk2

|

|

|

|

|

Note

Note| No straightening or welding work is possible on the axle body or on the axle pivot. |

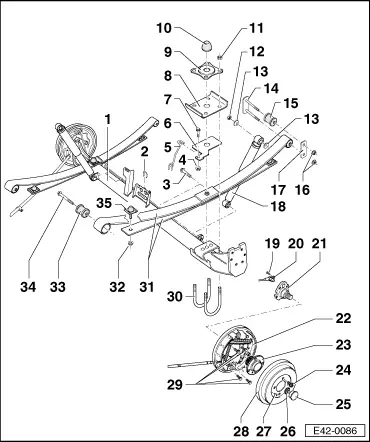

| 1 - | Axle body |

| q | Keep the contact surface and the screw holes for the axle rod free of paint and dirt. |

| 2 - | Support hook |

| q | For the brake lines |

| 3 - | Bolt |

| q | 65 Nm + 90° |

| 4 - | Hexagonal nut |

| 5 - | Hand brake cable support |

| 6 - | Intermediate plate |

| 7 - | Bolt |

| 8 - | Spring tension plate |

| 9 - | Stop plate |

| 10 - | Elastic limit |

| 11 - | Self locking nut |

| q | 40 Nm +180° |

| 12 - | Hexagonal nut |

| q | 65 Nm + 90° |

| 13 - | Washer |

| 14 - | Spring join element |

| q | With welded bolts |

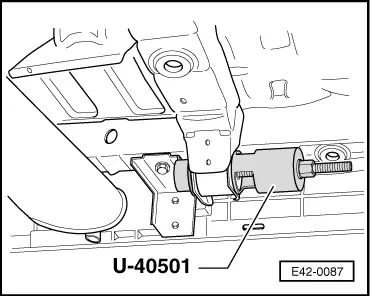

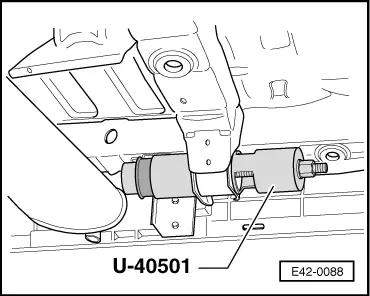

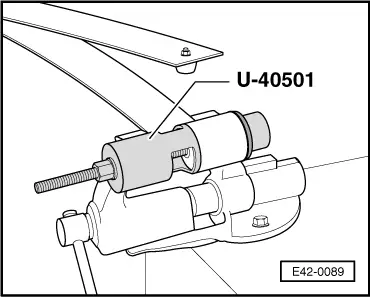

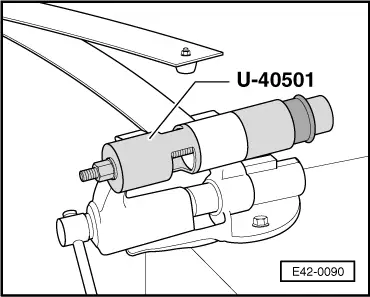

| 15 - | Metal/rubber bearing |

| q | On the longitudinal member |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| 16 - | Hexagonal nut |

| q | 65 Nm + 90° |

| 17 - | Spring join element |

| 18 - | Shock absorber |

| q | Check for leaks and noise |

| 19 - | Allen bolt |

| q | 10 Nm |

| 20 - | Revolution sensor |

| q | Only on vehicles equipped with ABS |

| 21 - | Axle stub |

| q | Straightening repairs are not permitted! |

| q | The screw threads cannot be reworked! |

| 22 - | Brake plate with brake shoes |

| q | Repairs → Brake system; Rep. Gr.46 |

| 23 - | Wheel hub and bearing assembly |

| The wheel bearing and hub are fitted together in one casing |

| This wheel hub and bearing unit does not require inspection or maintenance and has no play, therefore no adjustment or repair work can be done on it |

| 24 - | Wheel nut |

| q | 110 Nm |

| 25 - | Dustguard cover |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| q | Always replace if damaged (dented) |

| So that the seal is perfect, a new dust guard cover should always be used. Only in this way can perfect operation and a long useful life be guaranteed |

| 26 - | Dodecagonal self locking nut |

| q | 175 Nm |

| q | Replace after removing |

| 27 - | Star-head screw |

| 28 - | Brake drum |

| q | Before removing this, retract the brake pads through the wheel bolt hole → Fig. |

| 29 - | Bolt and washer |

| q | 60 Nm |

| 30 - | Spring flange |

| q | Alternate tightening of the attachment bolts so that both ends have the same depth |

| 31 - | Spring |

| q | These may be replaced individually |

| q | Removing and installing → Chapter |

| 32 - | Hexagonal nut |

| 33 - | Metal/rubber bearing |

| q | For the spring |

| q | Releasing → Fig. |

| q | Insertion → Fig. |

| 34 - | Bolt |

| q | 65 Nm + 90° |

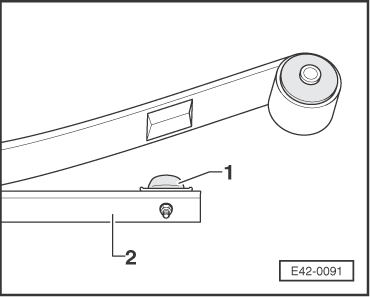

| 35 - | Rubber support spring |

| q | Note installation position → Fig. |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|