Leon Mk2

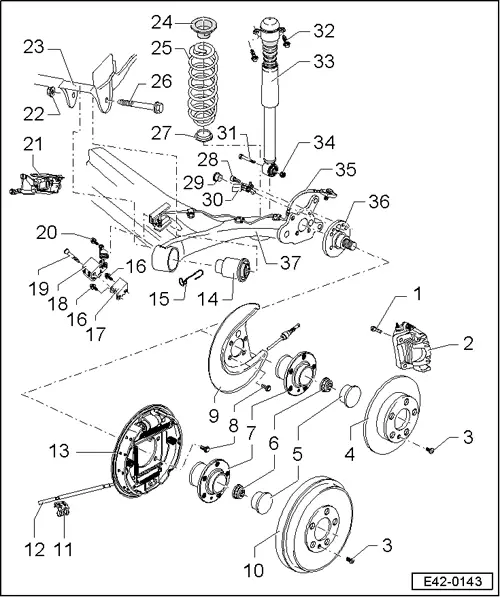

| Rear axle: removing and fitting |

Note

Note| t | No straightening or welding work is possible on the axle body or on the axle pivot |

| t | Always replace self-locking nuts following their removal |

| 1 - | 30 Nm + 30° |

| 2 - | Brake calliper |

| q | Rep. group → Rep. Gr.46 |

| 3 - | 4 Nm |

| 4 - | Brake disc |

| 5 - | Dustcap |

| q | Removing and installing → Fig. |

| q | replacing |

| So that the seal is perfect, a new dust guard cover should always be used. Only in this way can perfect operation and a long useful life be guaranteed |

| 6 - | 175 Nm |

| q | replacing |

| 7 - | Wheel hub and bearing assembly |

| q | For vehicles fitted with ABS, the sensor ring is fitted in the wheel bearing |

| q | Replace entire unit |

| q | removing and fitting → Chapter |

| q | Allocation: → Parts catalogue |

| – | The wheel bearing and hub are fitted together in one casing The bearing and the hub do not require inspection. Adjustments or repairs are not possible |

| 8 - | 30 Nm + further 1/4 (90°) |

| q | replacing |

| 9 - | Cover plate |

| 10 - | Brake drum |

| q | Repairs → Rep. Gr.46 |

| 11 - | Hand brake cable support |

| q | replacing |

| 12 - | Hand brake cable |

| q | Removing and fitting → Rep. Gr.46 |

| 13 - | Brake carrier with brake pads |

| q | Repairs → Rep. Gr.46 |

| 14 - | Bonded rubber bush |

| q | Removing and installing → Chapter |

| q | Installation position → Fig. |

| 15 - | Hand brake cable support |

| 16 - | 17 Nm |

| 17 - | Retainer |

| q | For the braking force regulator |

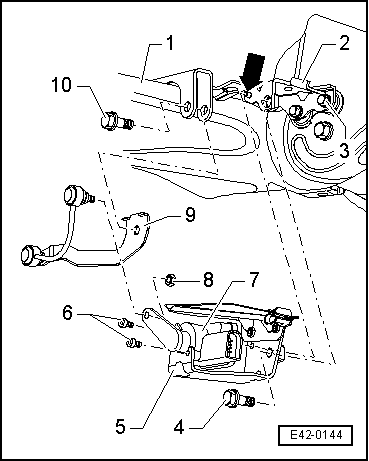

| 18 - | Brake pressure regulator |

| q | For vehicles without ABS |

| q | Verification and adjustment → Rep. Gr.47 |

| 19 - | 20 Nm |

| 20 - | 16 Nm |

| 21 - | Vehicle level sender -G76- |

| q | For vehicles with a gas discharge lamp |

| q | removing and fitting → Fig. |

| q | Verified by self-diagnosis → Vehicle diagnosis, testing and information system VAS 5051 |

| 22 - | 45 Nm + further 1/4 (90°) |

| q | replacing |

| q | Conditions for tightening → Chapter |

| 23 - | Support block for rear axle |

| q | Welded to the bodywork |

| 24 - | Upper spring support |

| q | Installation position → Fig. |

| 25 - | Coil spring |

| q | removing and fitting → Chapter |

| q | Check for imperfections in the paintwork |

| q | According the colour code |

| q | Always replace by axles |

| q | Allocation: → Parts catalogue |

| 26 - | 45 Nm + further 1/4 (90°) |

| q | Insert from the outside of the vehicle |

| q | Conditions for tightening → Chapter |

| q | replacing |

| 27 - | Lower base |

| q | Check for damage |

| 28 - | 8 Nm |

| 29 - | Seal |

| q | For vehicles without ABS |

| q | To cover the opening for the rev. sensor in the axle stub |

| 30 - | Revolution sensor |

| q | Before fitting the sensor, clean interior surface of opening and apply solid lubricating paste -G 000 650- |

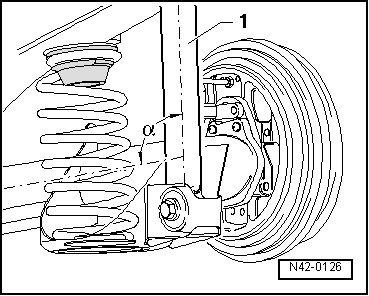

| 31 - | 40 Nm + further 1/4 (90°) |

| q | Insert from the interior of the vehicle |

| q | When tightening note the installation angle of the rear axle compared to the shock absorber → Fig. |

| q | replacing |

| 32 - | 30 Nm + further 1/4 (90°) |

| q | replacing |

| If the thread of the welded nut is damaged it may be repaired using a Heli-Coil thread insert |

| 33 - | shock absorber |

| q | Functional check |

| q | removing and fitting → Chapter |

| q | Disposal procedure → Chapter |

| q | Allocation: → Parts catalogue |

| 34 - | 40 Nm + further 1/4 (90°) |

| q | replacing |

| 35 - | Brake pipe |

| Vehicles with disc brakes |

| q | With hollow bolt and sealing washers |

| q | Do not dismantle, replace complete |

| q | Hollow bolt tightening torque: 38 Nm |

| 36 - | Axle connection |

| q | Straightening repairs are not permitted! |

| q | The screw threads cannot be reworked! |

Note

Note

|

|

|

|