Leon Mk2

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

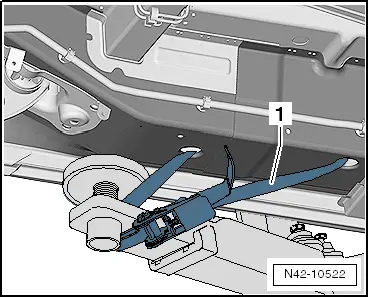

| Specified torques |

| Component | Tightening torque | ||

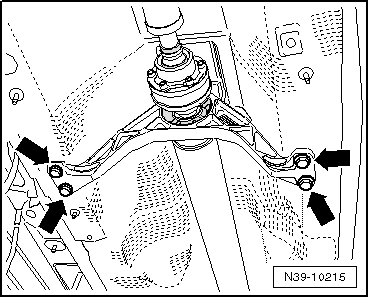

Subframe to body

| 90 Nm and then turn 90° further | ||

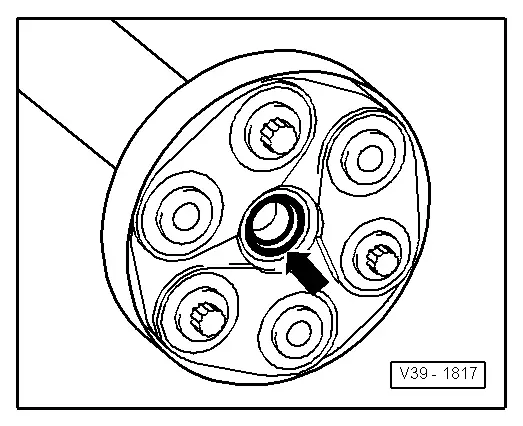

| Shock absorber to wheel bearing housing | 180 Nm | ||

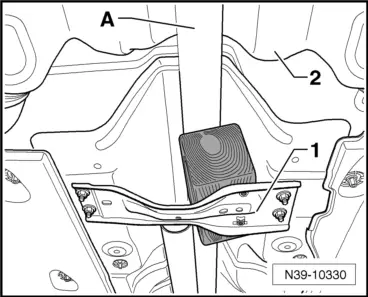

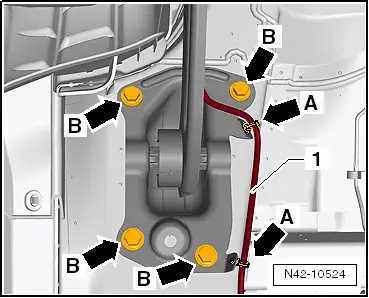

Mounting bracket to body

| 50 Nm and then turn 45° further |