Leon Mk2

|

| Special tools and workshop equipment required |

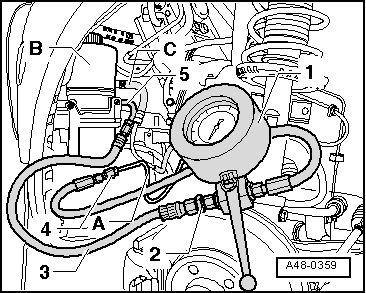

| t | Oil extractor -SAT 1100-, see equivalent → Anchor |

| t | Tightening torque -SAT 8010-, see equivalent → Anchor |

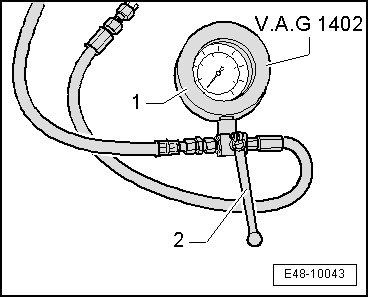

| t | Power steering tester -V.A.G 1402- |

| t | Adapter -VAG 1402/1A 2- |

| t | Adapter -V.A.G 1402/3- |

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

| Engines | Pressure specification | |

| MPa | bar | |

| Petrol | 9,6...10,4 | 96...104 |

| Diesel | 9,6...10,4 | 96...104 |

Note

Note

|