| –

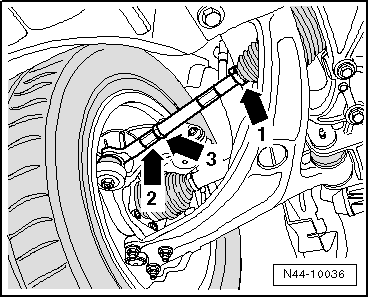

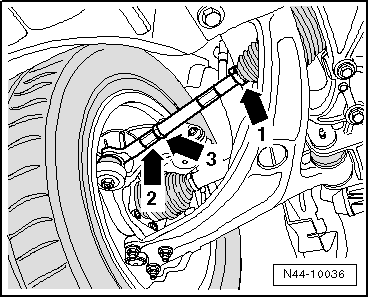

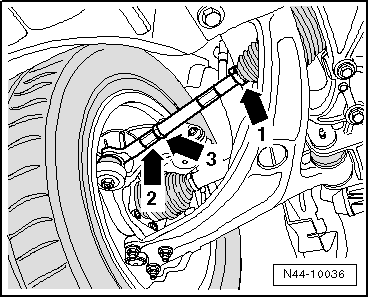

| Mark position of nut -arrow 3- on track rod. |

| –

| Loosen nut -arrow 3-, counterholding on track rod ball joint -arrow 2-. |

| –

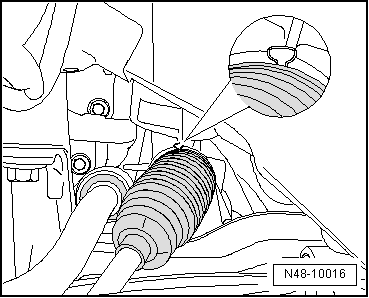

| Loosen spring-type clamp -arrow 1- on boot using hose clip pliers -V.A.G 1275- and push onto track rod. |

| –

| Remove hose clip and detach rubber boot from steering box housing. |

| –

| Now unscrew track rod from track rod ball joint. |

| –

| Detach rubber boot with spring-type hose clip from track rod. |

Note | t

| Renew complete steering box if there are signs of corrosion, damage, wear or dirt on the steering rack. |

| t

| The complete steering box must also be renewed if there is no visible lubricating film on the steering rack. |

Caution | Do not grease steering rack. |

|

| –

| Turn steering wheel to straight-ahead position. |

| –

| Fit new hose clips and rubber boot onto track rod. |

| –

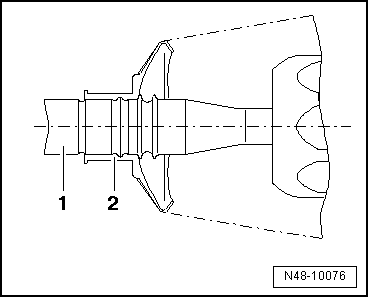

| Screw in track rod until the mark applied upon removal is just visible. |

|

|

|

Note

Note Note

Note

Caution

Caution