Leon Mk2

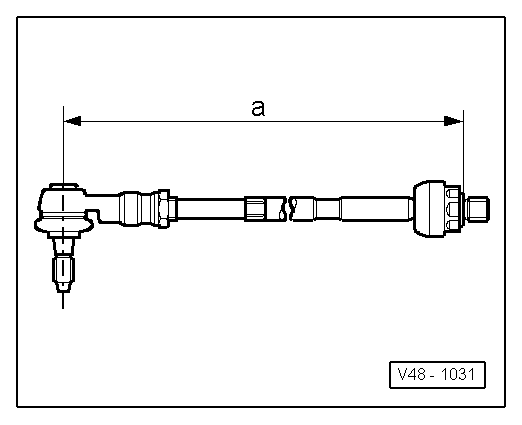

| Removing and installing track rod |

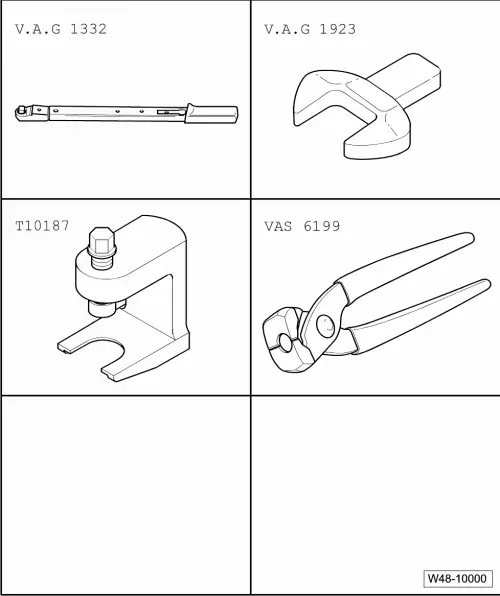

| Special tools and workshop equipment required |

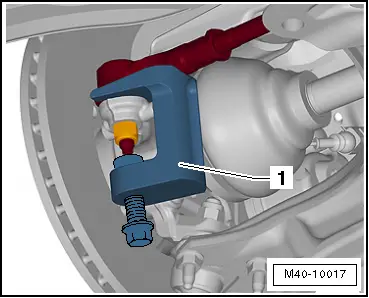

| t | Ball joint puller -3287 A- |

| t | Pliers for clamps -V.A.G 1275- |

| t | Torque wrench -V.A.G 1332- |

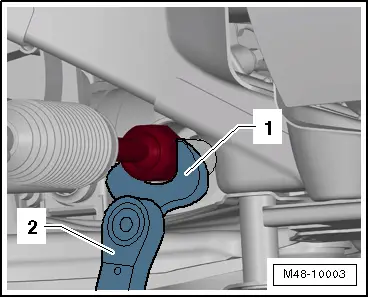

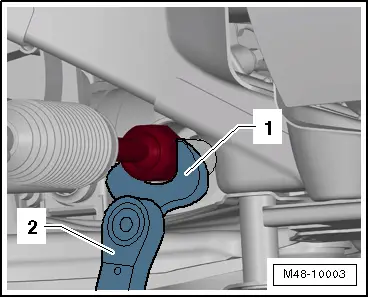

| t | Open-end spanner attachment (38 mm) -V.A.G 1923- |

| t | Locking pliers for Phaeton steering box -VAS 6199- |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Tightening torque | ||

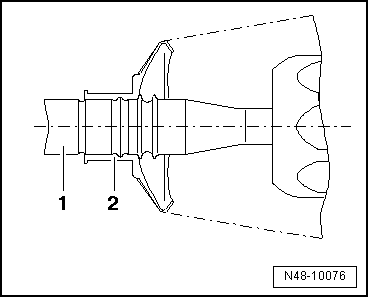

| Track rod to steering rack | 100 Nm | ||

| Track rod ball joint to track rod | 70 Nm | ||

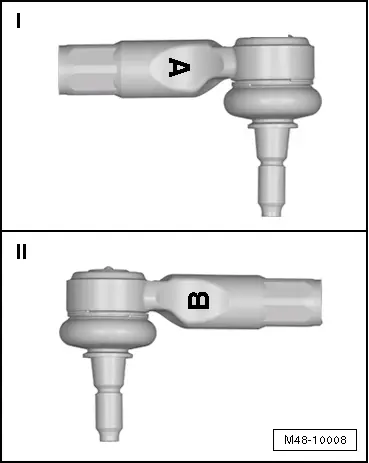

Track rod ball joint to wheel bearing housing

| Tighten to 100 Nm, then loosen (turn back) 180° and retighten to 100 Nm |

Caution

Caution