| –

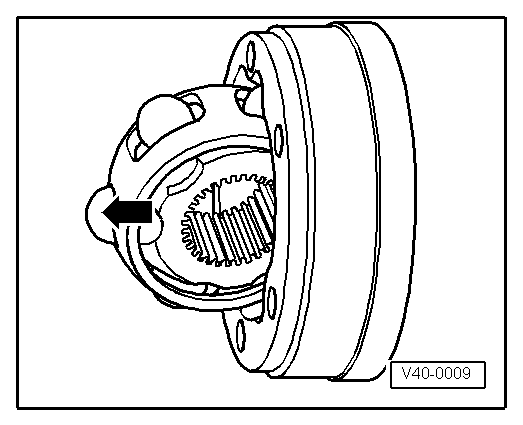

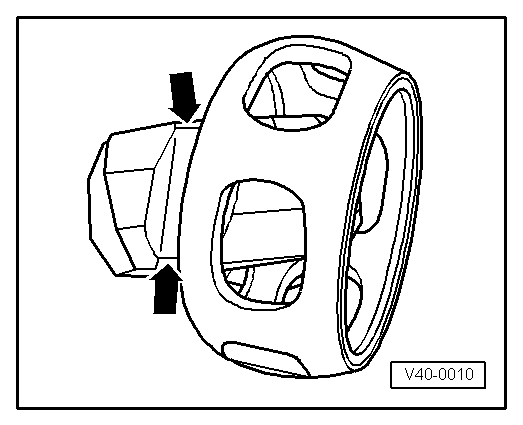

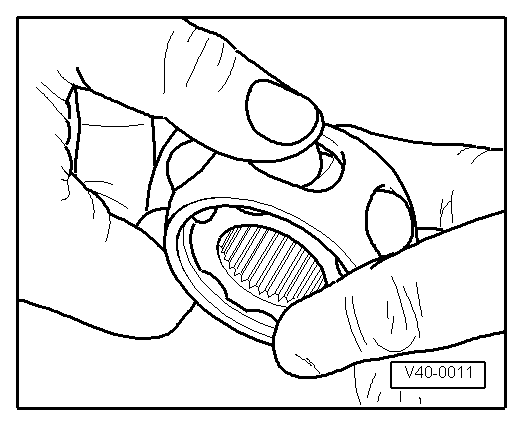

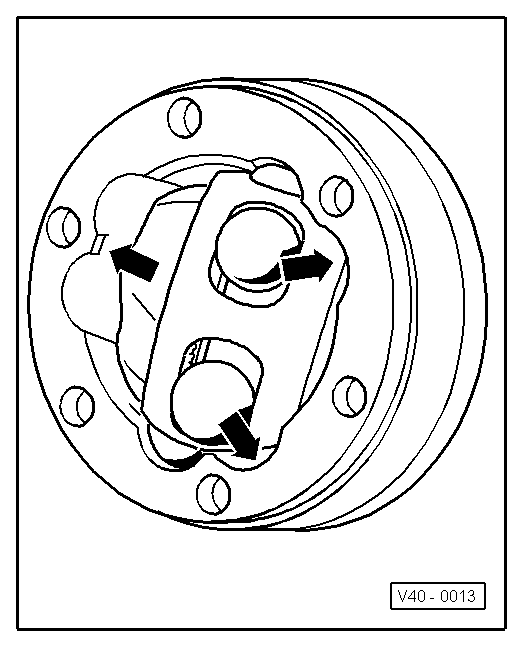

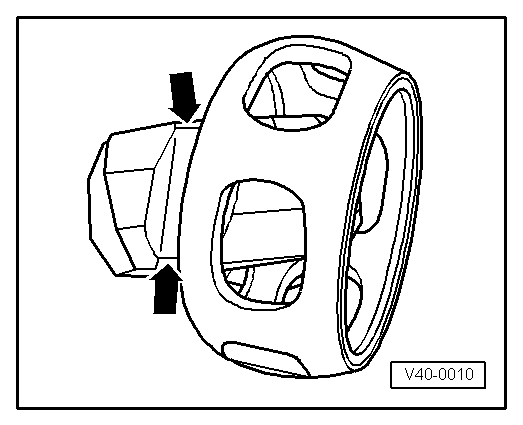

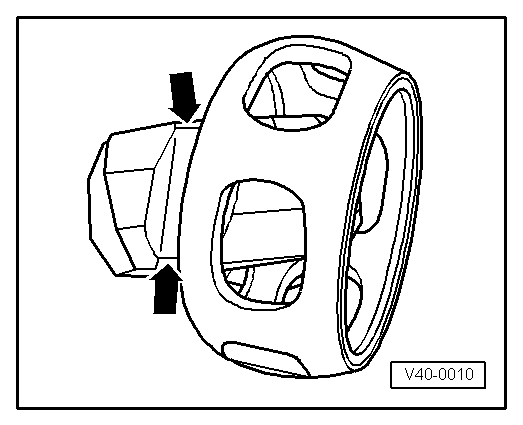

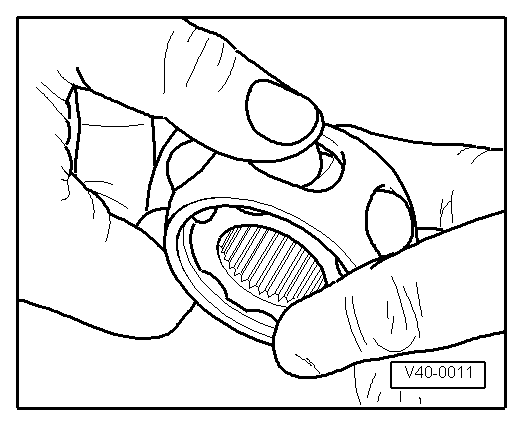

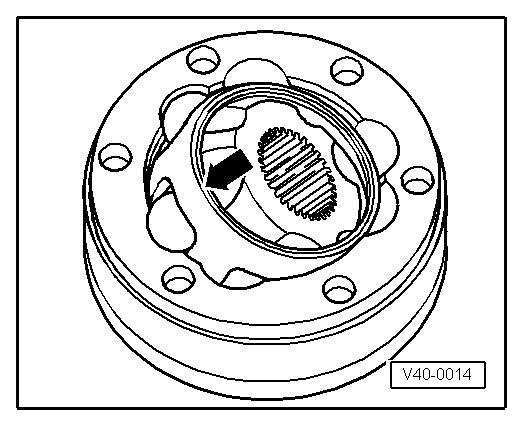

| Tilt ball hub out of ball cage over ball track -arrows-. |

| –

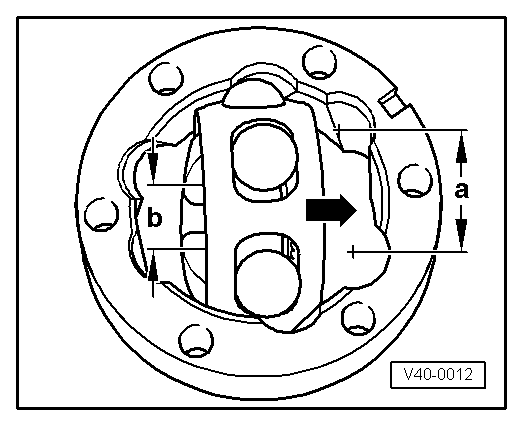

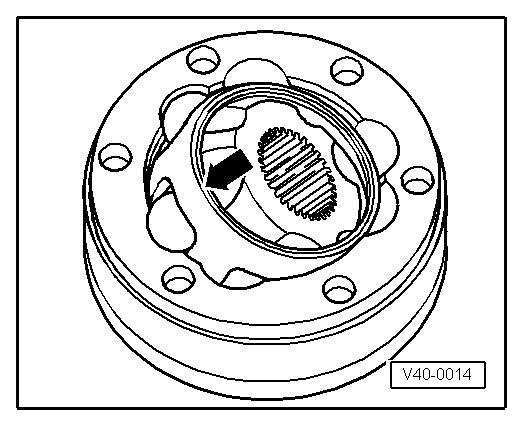

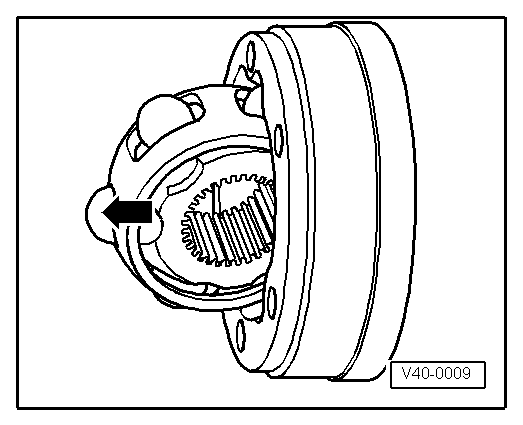

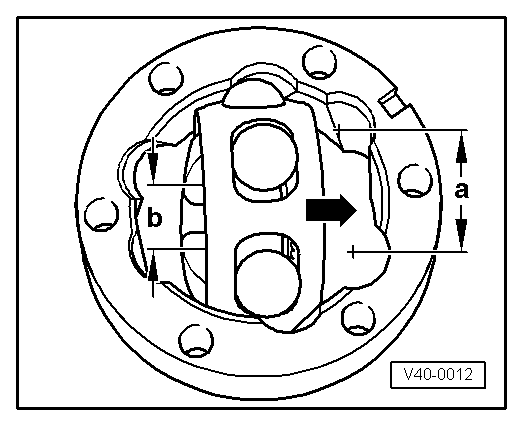

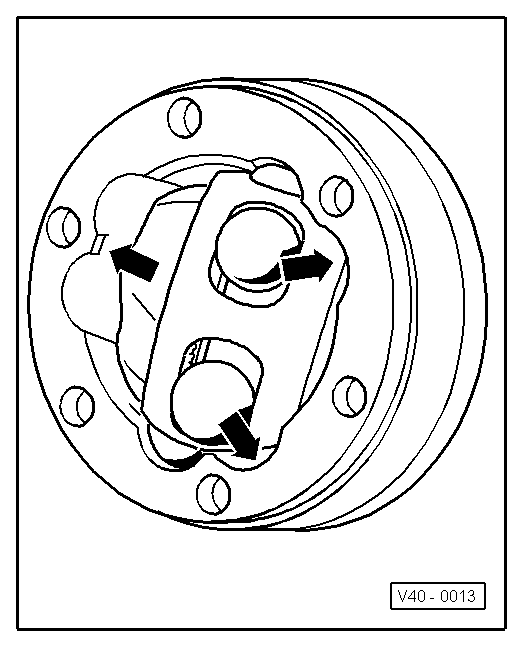

| Check joint, ball hub, ball cage and balls for indentations (pitting) and signs of seizure. |

| Excessive backlash in joint will be noticed as a knock during load changes. In such cases the joint must be renewed. Polished areas and tracks from balls are not a reason for changing the joint. |

|

|

|

Note

Note

Note

Note