Leon Mk2

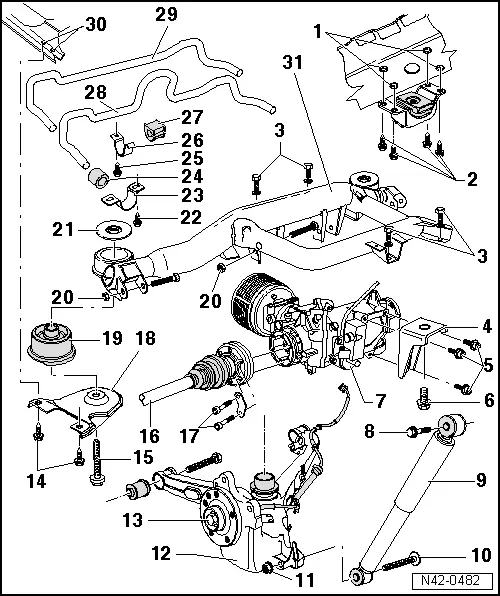

| Assembly overview - rear axle beam, syncro |

| Components not shown, such as the spring, rubber bush etc., are described from Page → Chapter onwards |

Note

Note| t | Welding and straightening on wheel locating/supports is not permissible. |

| t | Always renew self-locking nuts. |

| 1 - | Thread in cross-member |

| If the welded nut threads in the cross member are damaged, the thread can be serviced with Heli-coil thread insert. |

| Repairing thread in cross member → Chapter |

| This repair is only possible if the bearing bracket is secured with bolts → Item M 10 x 30. |

| 2 - | Hexagon bolt |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| q | M 10 x 25; 65 Nm |

| q | M 10 x 30; 50 Nm and turn 90° further |

| q | Always renew after removing |

| 3 - | Hexagon bolt, |

| q | 30 Nm + 90° further |

| q | Renew each time after removing. |

| 4 - | Bearing bracket |

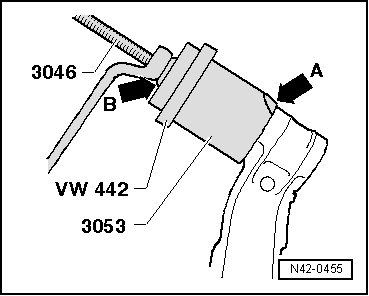

| 5 - | Multi-point socket head bolt |

| q | 30 Nm + 90° further |

| q | Renew each time after removing. |

| q | Use multi-point socket 14 (commercial type). |

| 6 - | Hexagon bolt |

| q | 260 Nm |

| q | Renew each time after removing. |

| 7 - | Final drive |

| q | Removing and installing → Rep. Gr. 39; Removing and installing rear final drive. |

| 8 - | Hexagon bolt |

| q | 110 Nm |

| q | Renew each time after removing. |

| 9 - | Gas-filled shock absorber |

| q | Removing and installing → Chapter. |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| 10 - | Hexagon bolt |

| q | Renew each time after removing. |

| 11 - | Nut |

| q | 130 Nm |

| q | Renew each time after removing. |

| 12 - | Suspension link |

| 13 - | Wheel bearings |

| q | Repairing → Chapter. |

| 14 - | Hexagon bolt |

| q | 100 Nm |

| 15 - | Hexagon bolt |

| q | 170 Nm |

| q | Renew each time after removing. |

| 16 - | Drive shaft |

| q | Removing and installing → Chapter. |

| 17 - | Multi-point socket head bolt |

| q | Torque setting → Item. |

| 18 - | Strut |

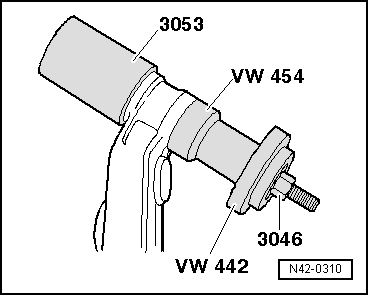

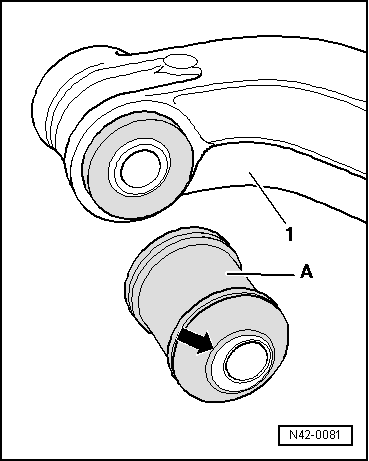

| 19 - | Bonded rubber bush |

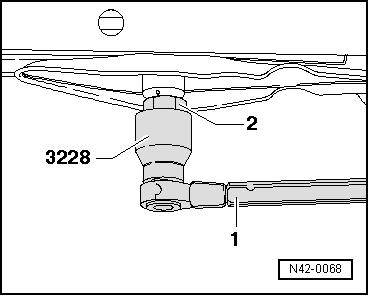

| q | Pressing out → Fig.. |

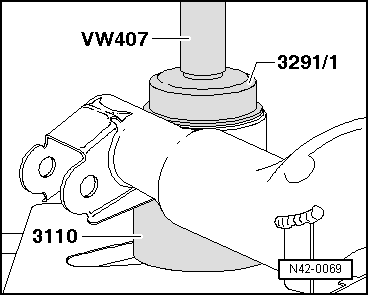

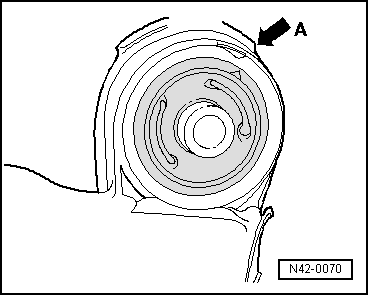

| q | Mark installation position → Fig.. |

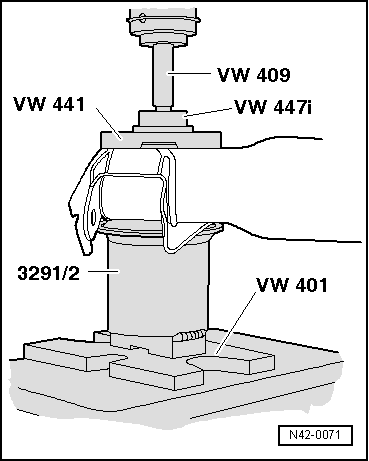

| q | Pressing in → Fig.. |

| 20 - | Nut |

| q | 170 Nm |

| 21 - | Backing plate |

| 22 - | Hexagon bolt |

| q | 30 Nm |

| 23 - | Clamp |

| 24 - | Rubber bush |

| 25 - | Hexagon bolt |

| q | 30 Nm |

| 26 - | Clamp |

| 27 - | Rubber bush, slotted |

| 28 - | Anti-roll bar |

| q | For vehicles up to 03.00 |

| 29 - | Anti-roll bar |

| q | For vehicles from 04.00 |

| 30 - | Threads in longitudinal member |

| If thread is damaged → Chapter. |

| 31 - | Axle beam |

| q | Aligning axle beam to vehicle → Chapter. |

Note

Note

|

|

|

|

| Installation position | Modification |

| Eccentricity upwards → Note | Negative camber modification |

| Eccentricity downwards → Note | Positive camber modification |

| Eccentricity towards the front → Note | Positive toe modification |

| Eccentricity to the rear → Note | Negative toe modification |

|

|

|

|

|

|

|

|

|