| –

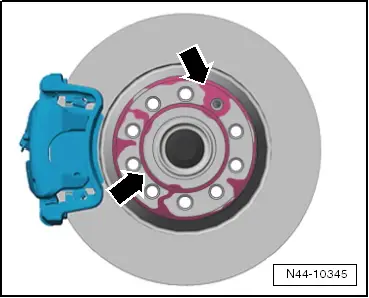

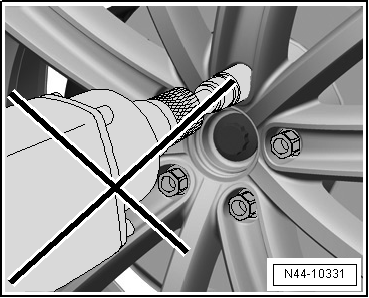

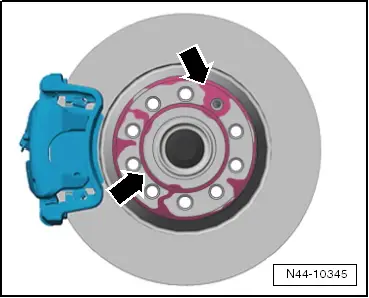

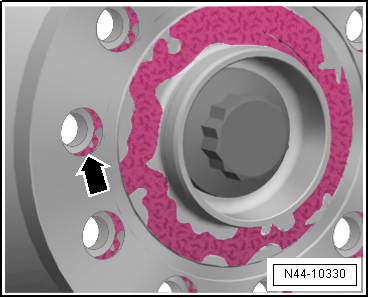

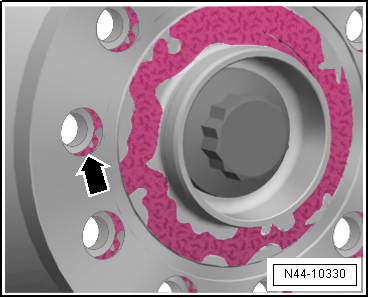

| Check whether the wheel bolts can be easily screwed in by hand. The thread of the wheel nuts should not come into contact with the brake disc opening -arrow-. |

| If the thread of the wheel bolt touches the opening -arrow-, turn the brake disc as necessary. |

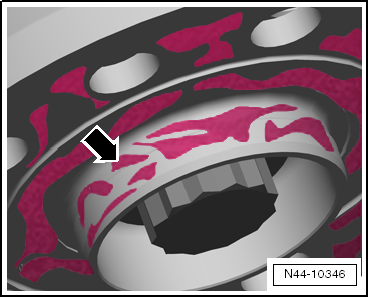

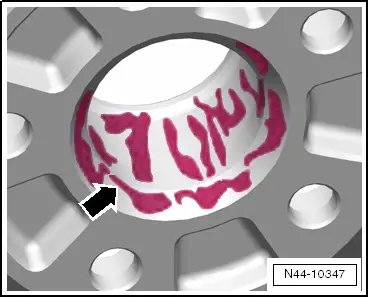

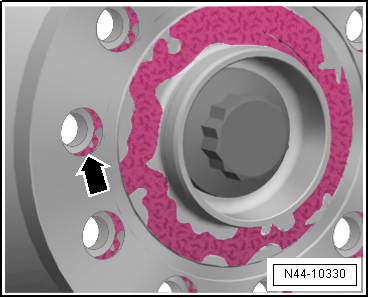

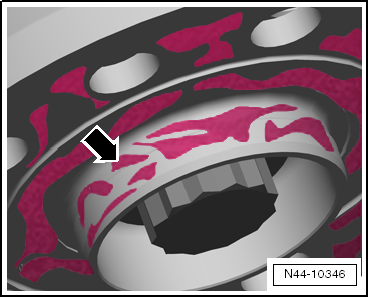

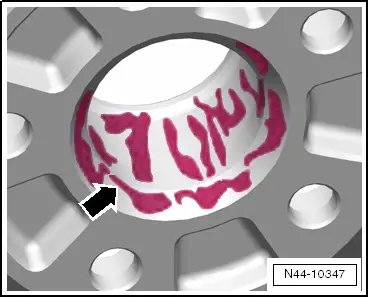

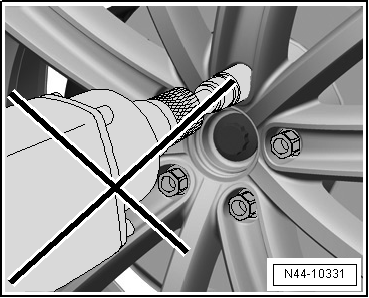

| If necessary, remove dirt and corrosion, oil or grease from the contact surfaces, threads in the wheel hub and/or wheel bolts as necessary. |

WARNING | Wheel bolts that are damaged, severely corroded or are difficult to remove must be replaced. |

|

|

|

|