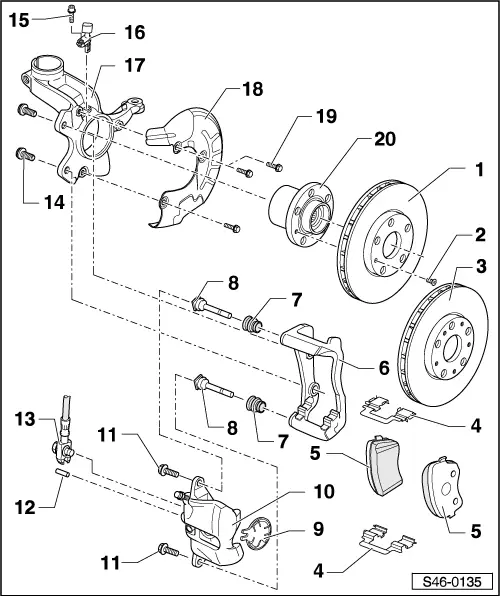

Repairing Front Brake for Fabia Mk1: Floating Caliper Disc Brake C54

Note

Note

|

| 1 - | Brake disc |

| q | the max. wheel run-out is not marked |

| q | released combination of a brake disc without marking and a wheel hub with marking |

| q | with a fixing hole for the wheel hub |

| q | Thickness: 25 mm |

| q | Wear limit: 22 mm |

| q | always replace axle-wise |

| q | for removing, first of all unbolt brake caliper complete from wheel bearing housing |

| q | Do not use force to separate the brake discs from the wheel hub, if necessary use rust solvent; as you could otherwise damage the brake discs. |

| 2 - | 4 Nm |

| 3 - | Brake disc |

| q | with a marking approx. 5 mm wide for marking the maximum wheel run-out |

| q | released combination of a brake disc with marking and a wheel hub without marking |

| q | with 5 fixing holes for the wheel hub |

| q | Thickness: 25 mm |

| q | Wear limit: 22 mm |

| q | always replace axle-wise |

| q | for removing, first of all unbolt brake caliper complete from wheel bearing housing |

| q | Do not use force to separate the brake discs from the wheel hub, if necessary use rust solvent; as you could otherwise damage the brake discs. |

| 4 - | Pad retaining plate |

| q | always replace when changing the brake pads |

| q | contained in the repair kit for brake pads |

| q | fit on before installing brake pads |

| 5 - | Brake pads |

| q | with wear indicator |

| – | with a corresponding wear (limit: 2 to 3 mm) the warning light in the dash panel insert lights up |

| q | Thickness: 18,6 mm (including the support plate) |

| q | Wear limit: 2.0 mm without supporting plate |

| q | Inspect thickness → BookletFabia |

| q | always replace axle-wise |

| q | do not unscrew the brake line when replacing the brake pad |

| q | removing and installing → Chapter |

| q | Observe the instructions for changing the pad → Chapter |

| 6 - | Brake carrier |

| q | is supplied as replacement part assembled with guide pin and protective caps as well as adequate quantity of grease on guide pins |

| q | if there is any damage to the protective caps or guide bolts fit a repair set (use the enclosed grease packing to lubricate the guide bolts) |

| q | also use grease packing for greasing the slot on the guide pin and brake caliper for attaching the protective cap |

| 7 - | Protective cap |

| q | contained in repair kit |

| q | insert into the slot of the brake carrier and of the guide pin; grease the slot first using grease packing from the repair kit |

| 8 - | Guide bolt |

| q | contained in repair kit |

| 9 - | Heat shield |

| q | always replace when changing the brake pads |

| q | contained in repair kit |

| q | insert into piston |

| Fitting location: insert plate at heat shield into the opening (slot) of the brake caliper |

| 10 - | Brake caliper |

| q | removing: |

| – | Use brake pedal load |

| – | Unscrew brake hose from brake caliper |

| – | Unbolt brake caliper from brake carrier |

| q | Installing: |

| – | Bolt brake caliper onto brake carrier |

| – | Screw the brake hose onto the brake caliper. |

| – | Remove brake pedal load |

| – | Bleeding Brake System → Chapter |

| q | repairing → Chapter |

| q | Observe the instructions for changing the pad → Chapter |

| 11 - | 30 Nm |

| q | replace after each removal |

| 12 - | Tensioning sleeve |

| 13 - | Brake hose with supports, hollow screw and gasket rings |

| q | must be replaced completely, do not dismantle |

| q | Tightening torque: 35 Nm |

| q | do not unscrew when replacing the brake pad |

| 14 - | 124 Nm |

| q | after the removal, clean the securing ribbing on the underside of the screw head |

| 15 - | Allan screw, 8 Nm |

| q | for speed sensor ABS |

| 16 - | ABS wheel speed sensor |

| 17 - | Wheel-bearing housing |

| 18 - | Cover plate |

| 19 - | 10 Nm |

| 20 - | Wheel hub with wheel bearing |

| q | with and without marking of the maximum wheel run-out |

| q | one can combine a wheel hub without marking of the maximum wheel run-out with a brake disc with marking of the maximum wheel run-out; the total wheel run-out of the floating caliper disc brake C54 will not be reduced |

| q | for vehicles with ABS the sensor ring is built into the wheel hub |

| q | replace after each removal, is destroyed during removal |

| q | removing and installing → Chapter |

| q | Assignment → Electronic Catalogue of Original Parts |