Fabia Mk1

|

|

|

Note

Note

|

|

Note

Note

|

|

| Tightening torques: |

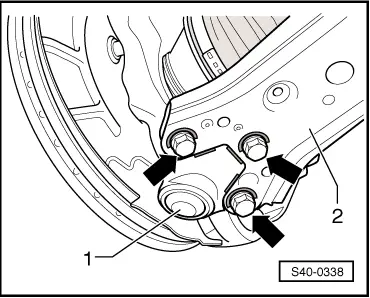

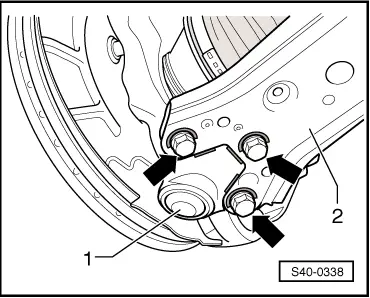

Drive shaft to flange shaft/gearbox

| → Item | ||||

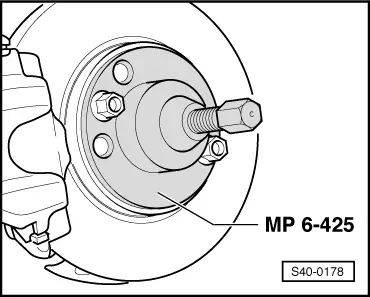

Twelve-point nut for securing the drive shaft to wheel hub with mechanical steering

| 50 Nm | ||||

Twelve-point nut for securing the drive shaft to wheel hub with power-assisted steering

| 50 Nm + 45° | ||||

Steering joint to track control arm

| 20 Nm + 90° | ||||

| Protection plate for inner joint of drive shaft | 25 Nm | ||||

| Wheel bolts | 120 Nm |