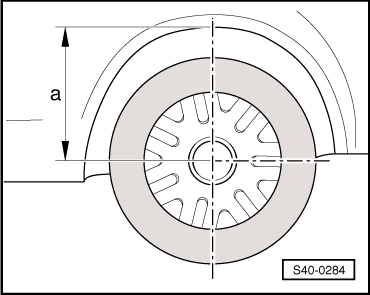

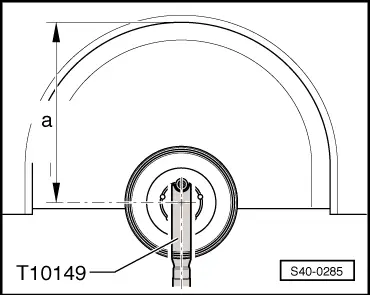

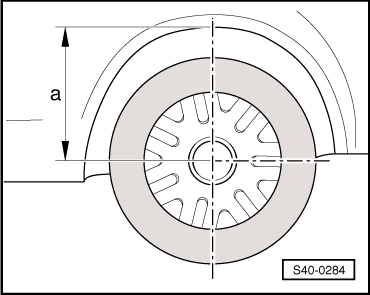

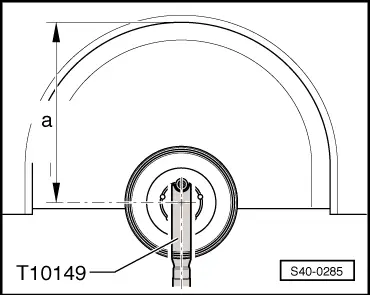

| Raise the wheel-bearing housing in the rebound state (unladen weight position) |

| Special tools and workshop equipment required |

| t

| Engine/gearbox jack, e.g. -V.A.G 1383/A- |

| t

| Tensioning strap -T10038- |

Note | All screws must always be tightened firmly in the unladen condition (unladen weight position) to the chassis parts with rubber-metal bearings - do not load the vehicle! |

| Weight of the vehicle with full fuel tank and full water reservoir for windscreen wiper/washer and headlamp cleaning system, spare wheel, tool kit, jack and without driver. The spare wheel, tool kit and jack must be located in the position prescribed by the vehicle manufacturer. |

| Rubber metal bearings have a limited slewing range. |

| Therefore the axle components with rubber-metal bearings must be put in a position before tightening, which corresponds to the position while driving. |

| Otherwise the rubber-metal bearing will be under tension and as a result, will have a lower life. |

| This position on the lift platform can be simulated by lifting out the corresponding wheel-bearing housing with the engine/gearbox jack e. g. -V.A.G 1383/A- and the support -T10149-. |

|

|

|