Fabia Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

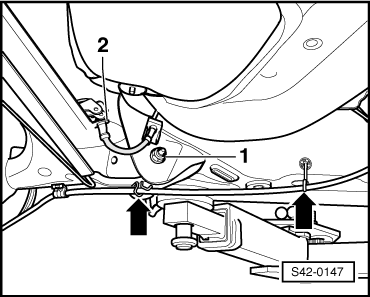

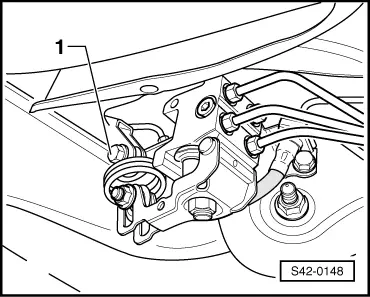

| Tightening torque: |

Rear axle to bearing bracket for axle

| 45 Nm + 90° | ||||

| Brake line holder to vehicle body | 16 Nm | ||||

| Screw for brake-power regulator | 16 Nm | ||||

| Wheel bolts | 120 Nm |

WARNING

WARNING