| –

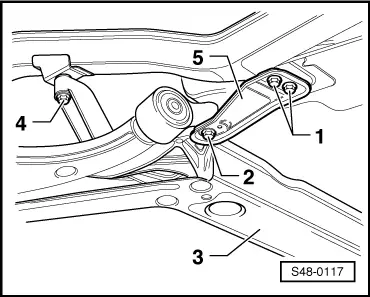

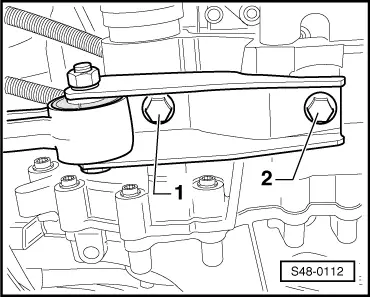

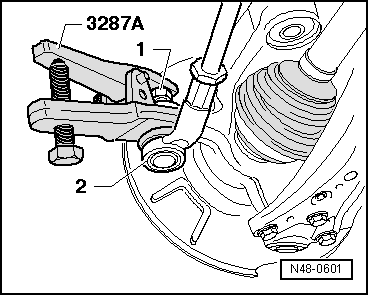

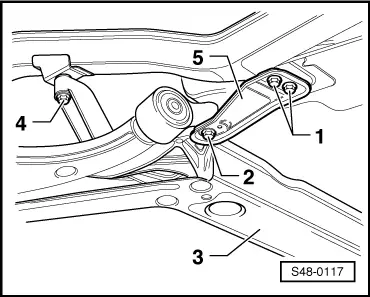

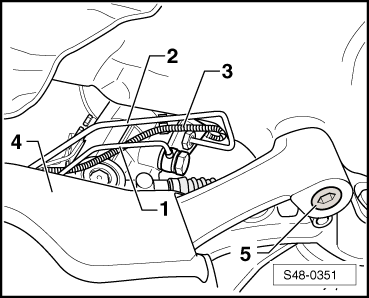

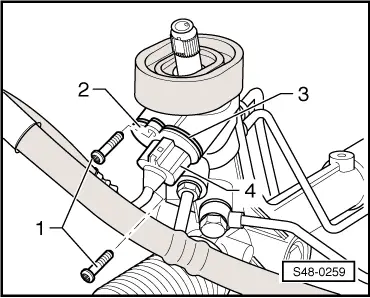

| Unscrew left screw -4- for assembly carrier -3-, screw in a fixing bolt of -T10096- and tighten to 20 Nm. |

| –

| Unscrew right screw -4- for assembly carrier (not shown in figure), screw in fixing bolt of - T10096- and tighten to 20 Nm. |

| –

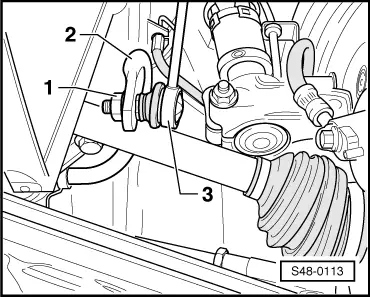

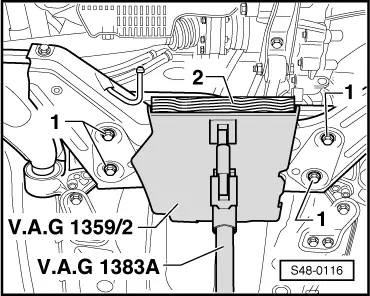

| Unscrew bolts -1- on both sides. |

| –

| Unscrew the left screw -2- and remove support -5-. |

| –

| Screw in fixing bolts of -T10096- to 20 Nm. |

| –

| Unscrew the right screw -2- and remove support -5-. |

| –

| Screw in fixing bolts of -T10096- to 20 Nm. |

| The fixing of the assembly carrier is completed once all 4 screws (Pos. -2- and -4-) are consecutively replaced with the fixing bolts. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution