| –

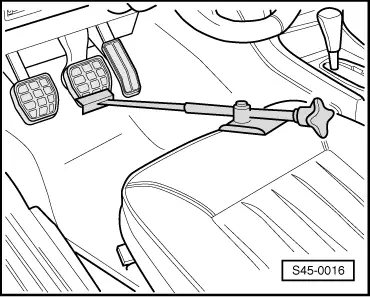

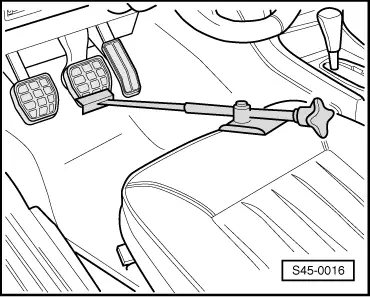

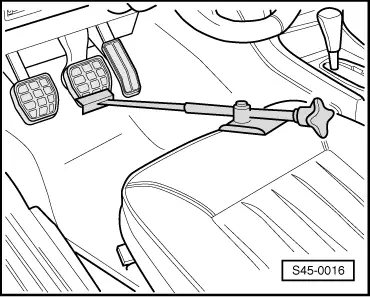

| Secure brake pedal with brake pedal arrester, e.g. - V.A.G 1238/B- or -V.A.G 1869/2-. |

| Overview of the work sequence for vehicle alignment |

| The following sequence of work steps must always be respected! |

| 1 - | Determine what chassis has been mounted in the vehicle. This information can be found on the vehicle data sticker → Chapter. |

| 2 - | Check camber on front axle, if necessary take the mean → Chapter |

| 5 - | Check track on front axle, if necessary adjust → Chapter |

| The following always applies! |

| Always check the transversal inclination of the vehicle before adjustment if one of the measuring values is outside the tolerance → Chapter. |

| Nominal values for vehicle alignment: |

|

|

|