| Check ignition coils with power output stage (engines with engine identification characters BBY, BKY, BBZ, BUD) |

| Special tools and workshop equipment required |

| t

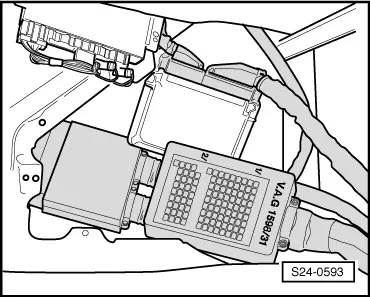

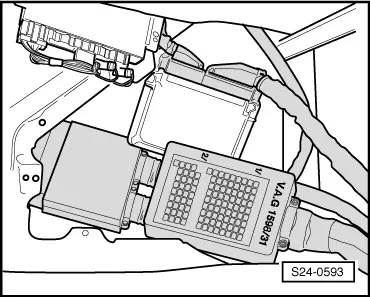

| Test box -V.A.G 1598/31- or -V.A.G 1598/22- |

| t

| Handheld multimeter, e.g. -V.A.G 1526 B- |

| t

| Measuring tool set, e.g. -V.A.G 1594 C- |

| t

| Diode test lamp, e.g. -V.A.G 1527- |

Note | Ignition coil and power output stage form a building unit. |

| Cylinder, which does not operate or misfire, determine as follows: |

| If a combustion misfiring was detected: |

| –

| Proceed with test on cylinder determined as defective. |

| If no combustion misfiring was detected: |

| –

| Successively remove contacts of the injectors while engine is running and monitor engine run, |

| –

| Compare spark plugs of all cylinders and pay attention to contaminated (covered with soot) electrodes. |

| If a defective cylinder was determined: |

| –

| Replace the spark plug of the defective cylinder with the one of another cylinder. |

| If the fault on this spark plug still exists: |

| If the given cylinder is still defective: |

| –

| Replace the ignition coil of the defective cylinder with the one of another cylinder. |

| If the fault on this ignition coil still exists: |

| If the given cylinder is still defective: |

| –

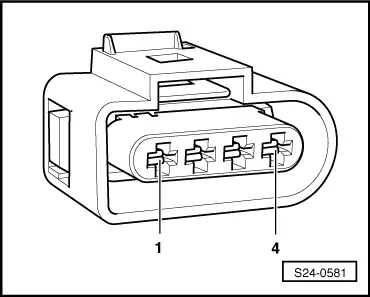

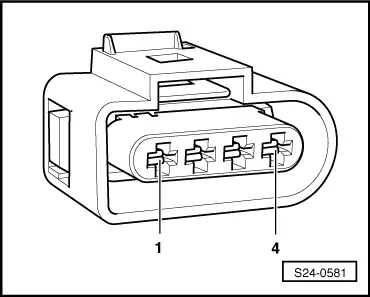

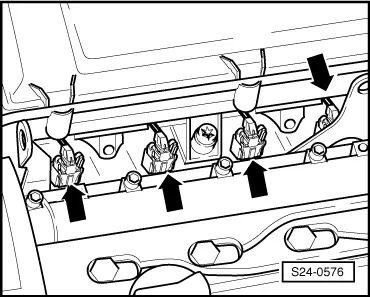

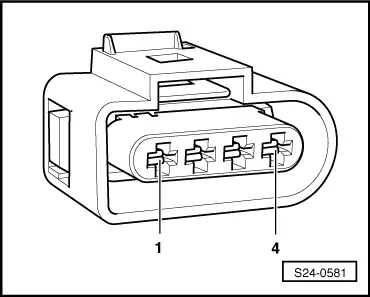

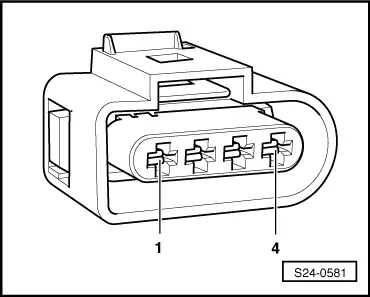

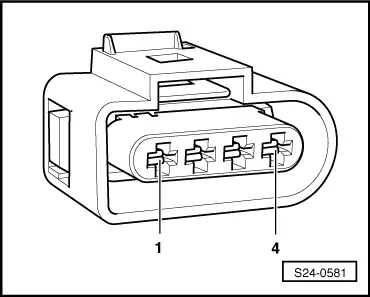

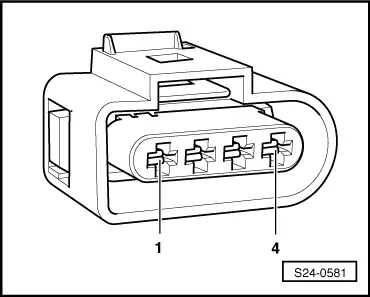

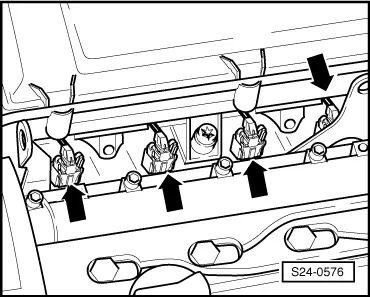

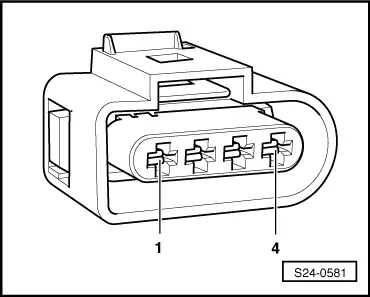

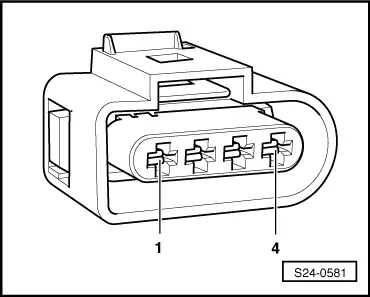

| Unplug the 4 pin plug connections from all ignition coils. |

|

|

|

Note

Note

Note

Note