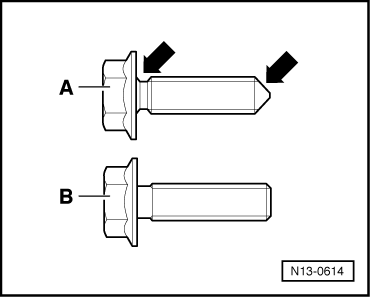

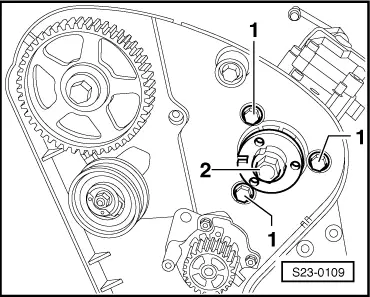

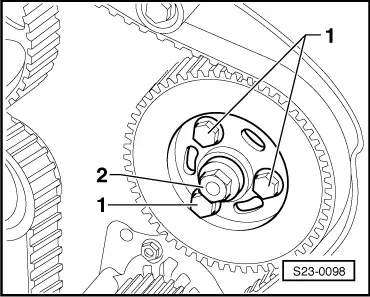

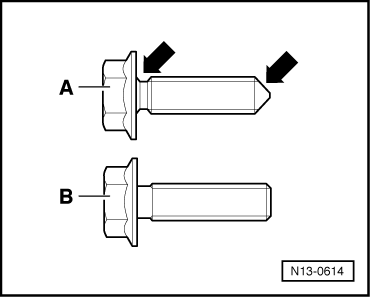

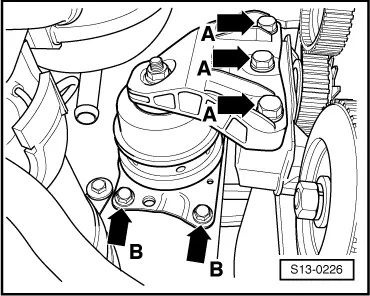

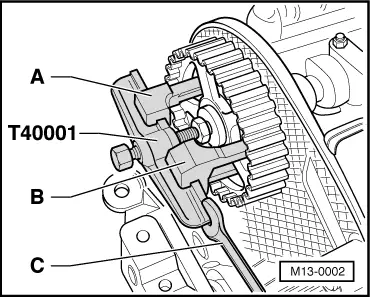

| Version -A-: Fixing bolts with relief on the thread stem and tip -arrows- |

| –

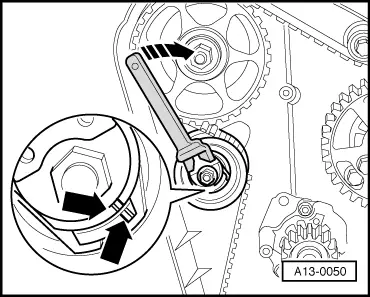

| Tighten the new fixing screws of the injection pump gear. |

Note | t

| After a dynamic test of the start of pump delivery tighten the fixing bolts a further 1/4 turn (90°). |

| t

| The fixing bolts must be used once only as they are antifatigue bolts. |

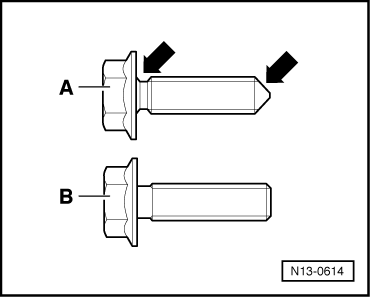

| Version -B-: Fixing bolts without relief on the thread stem and tip |

| –

| Tighten the old fixing screws of the injection pump gear. |

Note | Do not replace the fixing bolts. |

| Continued for all versions: |

| –

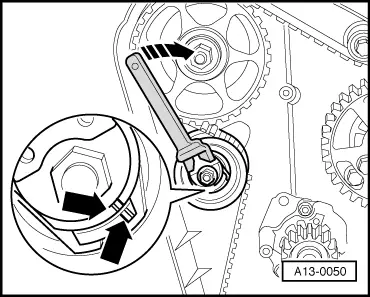

| Remove adjusting straightedge -MP 1-312- from the camshaft. |

| –

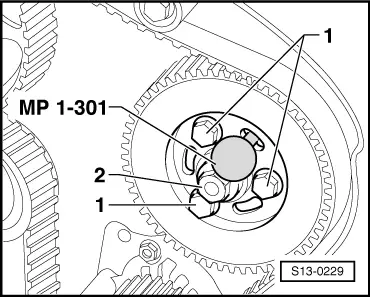

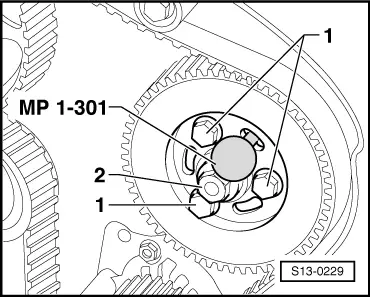

| Pull out the rig pin -MP 1-301-. |

| –

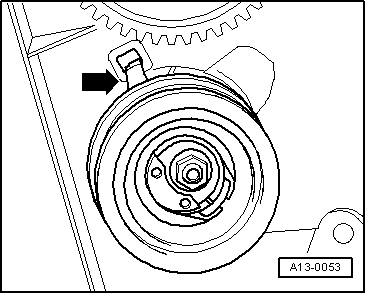

| Turn crankshaft two turns further in the direction of running of the engine and again position on TDC for cylinder 1. |

|

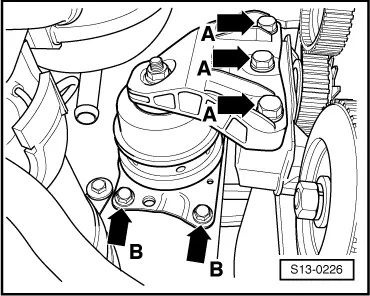

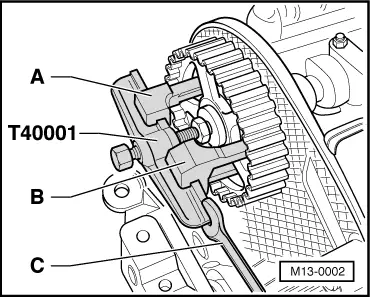

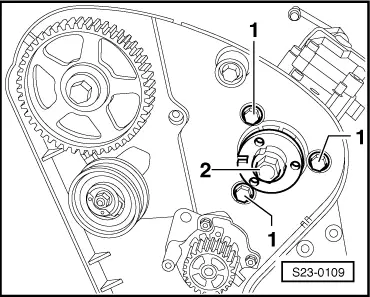

| the TDC marking on the flywheel,

the adjusting straightedge in the camshaft,

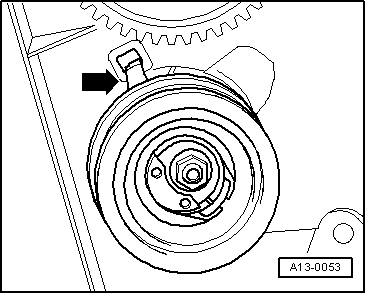

the rig drift in the injection pump gear,

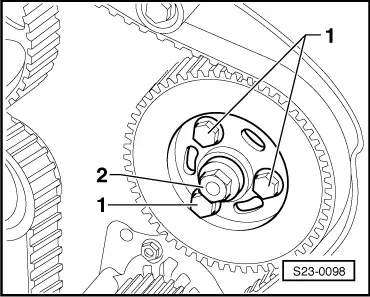

the setting of the tensioning pulley (notch/arrow) |

| –

| If the notch and arrow are not opposite one another, tighten the tensioning pulley and the fixing bolt to 25 Nm. |

| –

| Turn crankshaft two turns further in the direction of running of the engine until the crankshaft is again on TDC for cylinder 1. |

| –

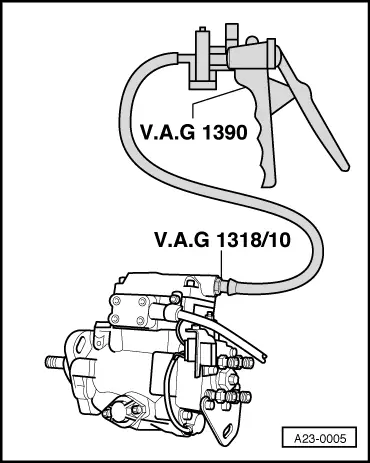

| Connect the injection lines, fuel feed line and electric wires. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note