| –

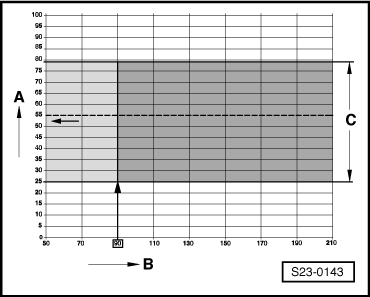

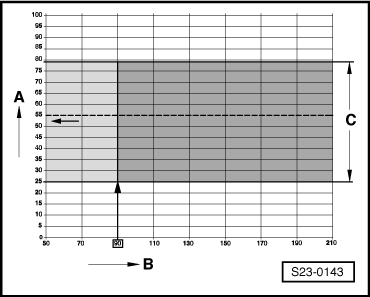

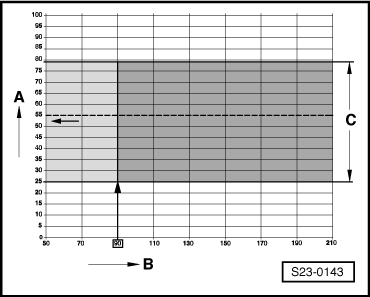

| The commencement of injection in display field 2 is dependent on the fuel temperature in display field 9. |

| A - | Display field 2, commencement of injection |

| B - | Display field 9, fuel temperature |

| C - | Nominal value range for commencement of injection |

| Numerical value 90 in display field 9 -B- corresponds in display field 2 -A- to a numerical value of 25...78. |

Note | No setting is required if during testing the commencement of injection is in the nominal value range -C-. |

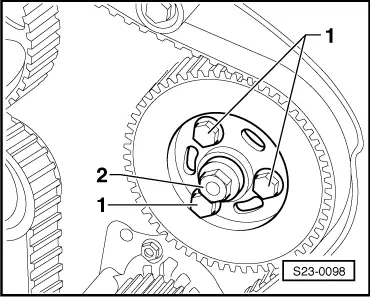

| If the commencement of injection is outside the nominal value range, adjust the commencement of injection as follows: |

| –

| Switch off the ignition. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note