Fabia Mk1

|

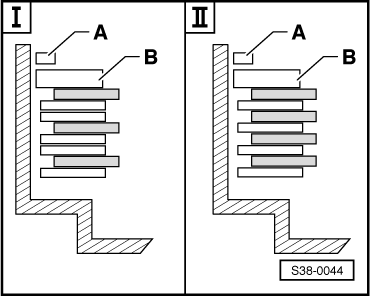

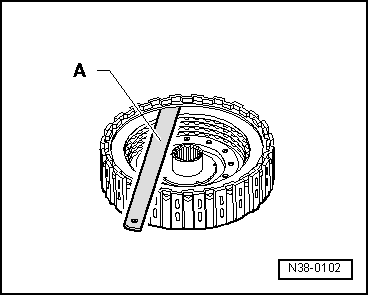

| Already when assembling, pay attention → Fig. to the number of plates and their fitting position |

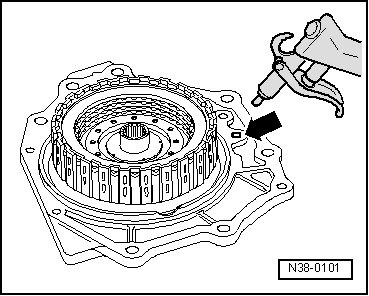

| Inspect operation of clutch → Fig. |

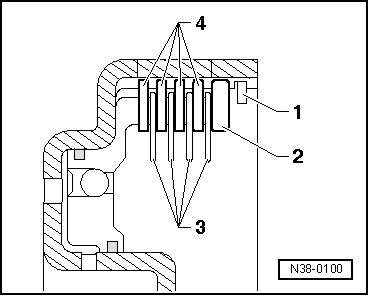

| 1 - | Circlip |

| q | release with a screwdriver |

| 2 - | Pressure plate |

| q | installing → Fig. |

| q | Determine thickness → Fig. |

| 3 - | Inner plate |

| q | installing → Fig. |

| q | Piece number → Chapter |

| 4 - | Outer plate |

| q | installing → Fig. |

| q | Piece number → Chapter |

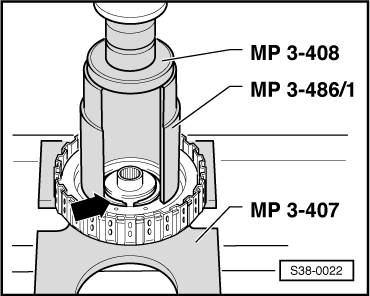

| 5 - | Circlip |

| q | removing and installing → Fig. |

| 6 - | Spring support plate |

| q | with springs |

| 7 - | Gasket ring |

| q | always replace |

| 8 - | Gasket ring |

| q | always replace |

| 9 - | Piston |

| q | differs depending on the engine version |

| q | assigned to gearbox identification characters as a spare part |

| q | moisten sealing lips with ATF before inserting |

| q | turn piston slightly when installing |

| q | after installing the piston must turn in the clutch bell |

| 10 - | Clutch bell |

|

|

|

|

|

|

|

|

| Component | Fitting dimension | Wear limit |

| Clutch -K3- | 1.8…2.2 mm | 2.4 mm |

|