| General Repair Information |

| To carry out gearbox repairs successfully and correctly, scrupulous care and cleanliness, as well as the proper tools, are essential requirements. Obviously, the generally valid basic safety rules apply to repair work. |

| A number of generally valid notes for individual repair operations (which are otherwise listed several times at numerous points in the workshop manual) are summarized here. They apply to this workshop manual. |

| t

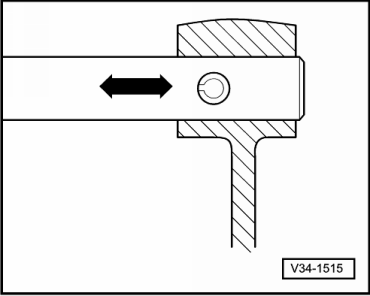

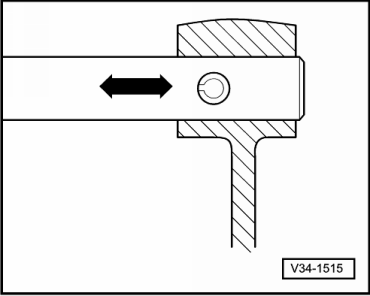

| When installing, ensure the dowel sleeves are correctly located between the engine and gearbox. |

| t

| If replacing the gearbox, pour in gear oil up to lower edge of filler hole. |

| t

| Thoroughly clean contact surfaces and apply sealant THREE BOND 1104. |

| t

| Apply sealant evenly - not too thick. |

| t

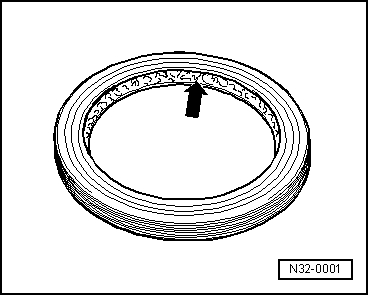

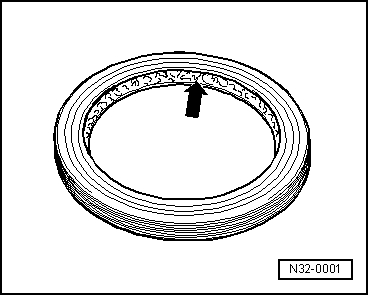

| Replace radial shaft seals. |

|

|

|