Fabia Mk1

Note

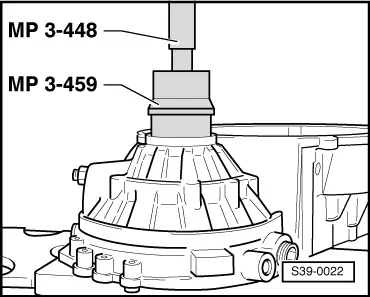

Note| t | Before installing heat the inner ring of the tapered-roller bearing to 100°C. |

| t | Replace both tapered-roller bearings together. |

| t | When replacing the tapered-roller bearing of the differential housing, gearbox housing or clutch housing adjust the differential → Chapter |

| t | Pos. 2 to 6 only applies for service. |

| 1 - | Gearbox housing |

| 2 - | Screw |

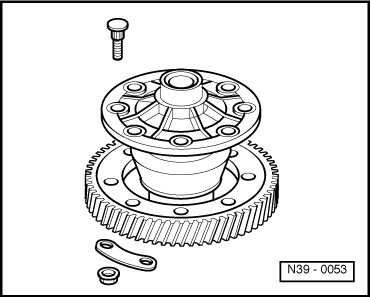

| 3 - | Differential housing |

| q | screw to pinion for final drive |

| 4 - | Pinion for final drive |

| q | series riveted |

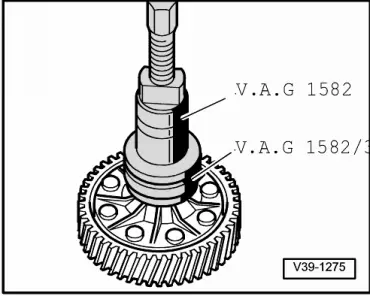

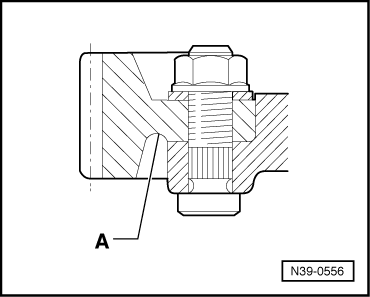

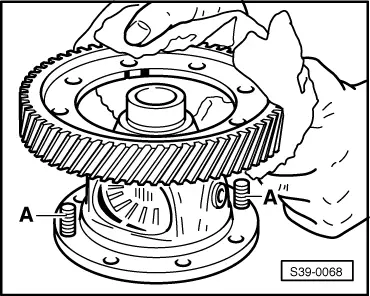

| q | screw → Fig. |

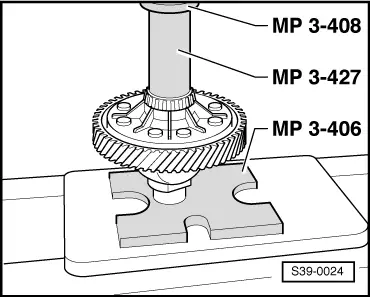

| q | heat to 100 °C before fitting |

| q | pressing off → Fig. |

| q | Fitting position → Fig. |

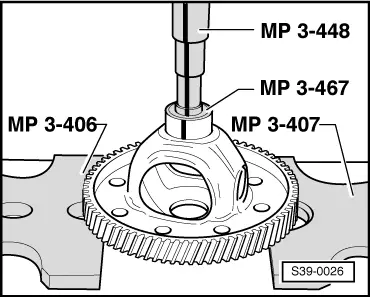

| q | place on the differential housing → Fig. |

| q | is paired with the output shaft, replace together |

| 5 - | Shim |

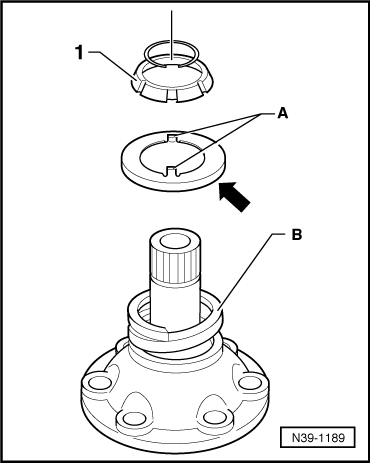

| 6 - | Nut, 70 Nm |

| 7 - | Adjusting washer |

| q | for differential |

| q | Determine thickness → Chapter |

| 8 - | Outer ring/tapered-roller bearing |

| q | removing → Fig. |

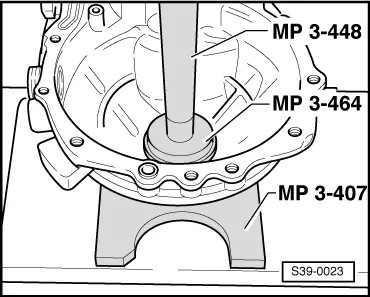

| q | installing → Fig. |

| 9 - | Inner ring/tapered-roller bearing |

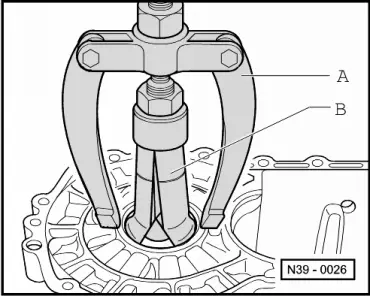

| q | remove → Fig. |

| q | pressing on → Fig. |

| 10 - | Differential housing |

| q | with riveted pinion for final drive |

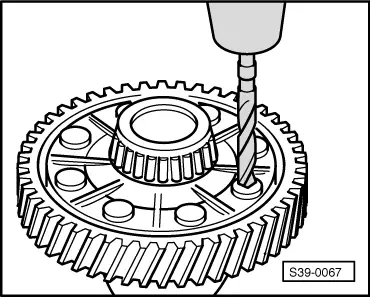

| q | when replacing the final drive pinion bore out the rivet heads → Fig. |

| q | Secure pinion for final drive → Fig. |

| 11 - | Drive wheel for speedometer |

| q | before pressing on the inner ring place it on the differential gear housing up to the stop |

| 12 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 13 - | Outer ring/tapered-roller bearing |

| q | pressing out → Fig. |

| q | installing → Fig. |

| 14 - | Clutch housing |

| 15 - | Bushing |

| q | for support of gasket ring Pos. 16 |

| q | removing and installing → Chapter |

| 16 - | Gasket ring |

| q | left - replace with installed gearbox → Chapter |

| q | right - replace with installed gearbox → Chapter |

| 17 - | Bushing and gasket ring, single version |

| q | replace damaged gasket ring with bushing → Chapter |

| q | Difference → Chapter |

| 18 - | 25 Nm |

| q | screw to threaded connector Pos. 26 to attach the flange shaft |

| 19 - | Flange shaft |

| q | removing and installing → Chapter |

| 20 - | Pressure spring for flange shaft |

| q | fitted behind flange shafts |

| 21 - | Thrust washer |

| q | Fitting position: flange to pressure spring, leg to conical ring |

| q | Fitting position of the changed thrust washer → Fig. |

| 22 - | Conical ring |

| q | with slots for thrust washer catch |

| q | Fitting position: Cone towards differential housing |

| 23 - | Retaining clip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

| 24 - | Stop disc compound |

| q | insert with gear oil |

| 25 - | Differential bevel gear large |

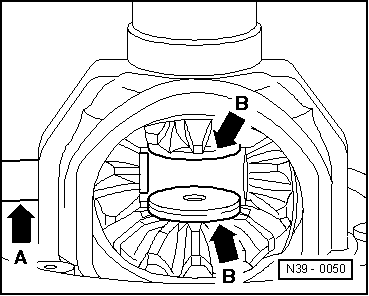

| q | installing → Fig. |

| 26 - | Threaded part |

| q | installing → Fig. |

| 27 - | Differential bevel gear shaft |

| q | drive out with drift -MP 3-510- |

| q | installing → Fig. |

| 28 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

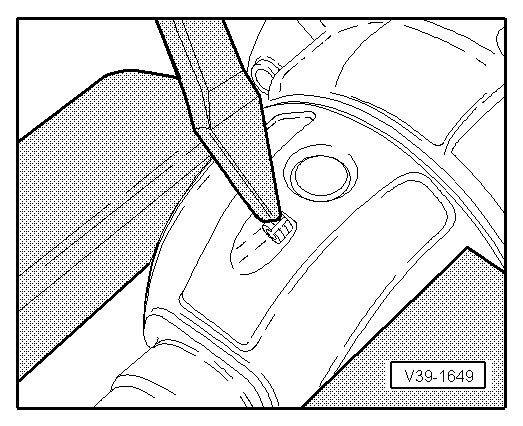

| q | removing and installing → Fig. |

| 29 - | Differential bevel gear small |

| q | installing → Fig. |

| 30 - | Differential bevel gear large |

| q | installing → Fig. |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|