| –

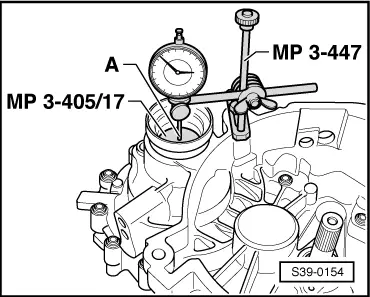

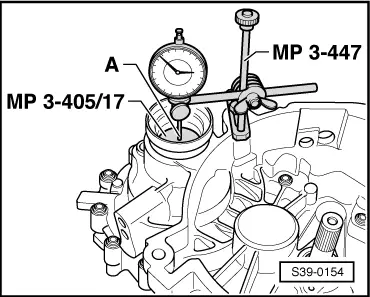

| Set up the measuring device and dial gauge (3 mm measuring range), dial gauge extension -A- approx. 30 mm). |

| –

| Set the dial gauge to 0 with 1 mm bias. |

| –

| Move the differential gear up and down, read off and write down the clearance on the dial gauge. (Example: 1,50 mm). |

Note | Do not turn the differential while measuring as otherwise the bearings will settle and the measuring result will be inaccurate. |

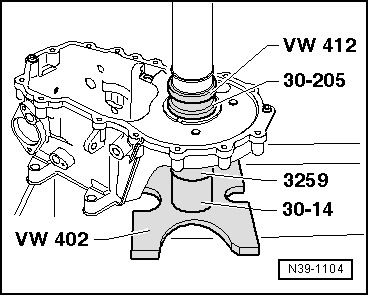

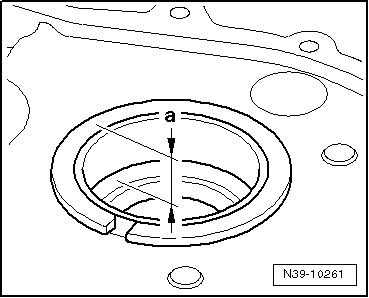

| Determining adjusting washer S 2 |

| The required bearing preload is reached by adding to the value measured for S 2 (for example: 1.50 mm) a constant value for pressure (0.25 mm for aluminium housings and 0.35 mm for magnesium housings). |

|

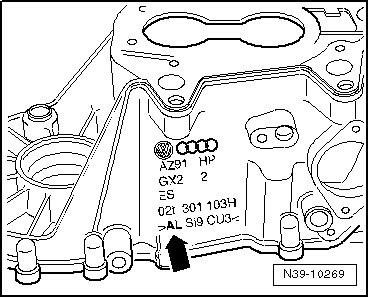

| For housing in magnesium version: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note