| –

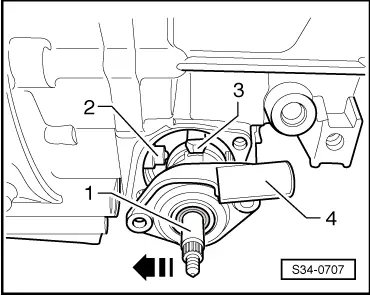

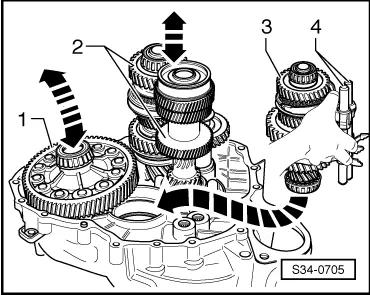

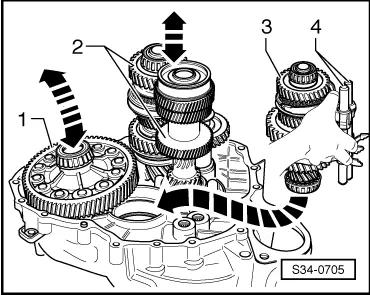

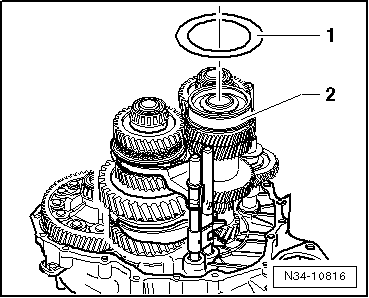

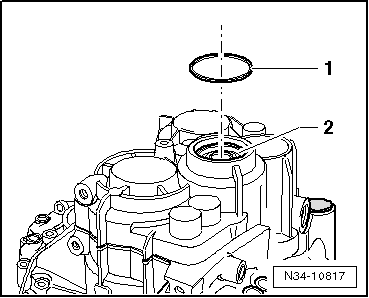

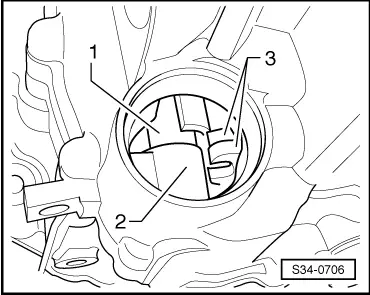

| Insert the differential -1-. |

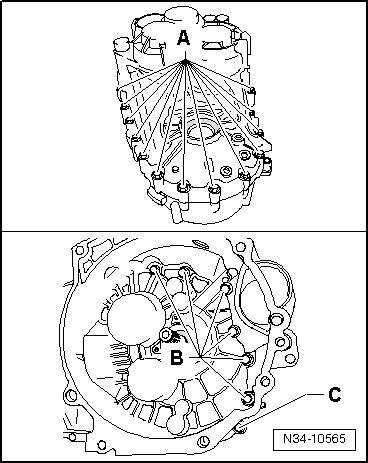

Note | For further installation of the shafts in the clutch housing a second mechanic is required. |

| –

| Take the output shaft gears 1 through 4 -3- with the gear shift rods -4- in the right hand as shown. |

| –

| Slightly lift the differential with the left hand. |

| –

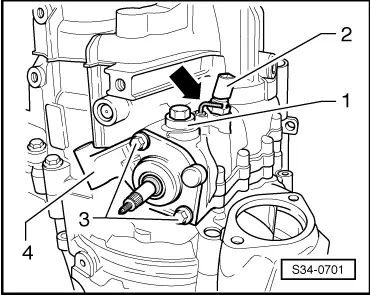

| At the same time the 2nd mechanic lifts the drive shaft, the output shaft 5th/6th gear and reverse gear -2- together with the reverse shaft. |

| –

| Insert the output shaft gears 1 through 4 in -the direction of the arrow-. |

| l

| The serrations of the drive shaft, output shafts and final drive/differential must be in mesh. |

| –

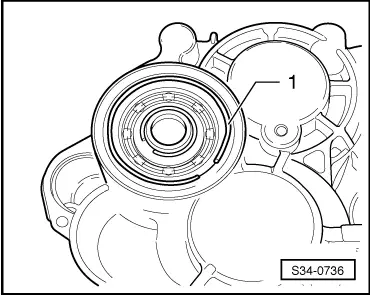

| Place the shafts and the differential in their bearing assembly. |

|

|

|

Note

Note

Note

Note

Note

Note