| Disassembling and assembling the drive shaft for gearbox up to gearbox manufacturing date 06.03 |

| Special tools and workshop equipment required |

| t

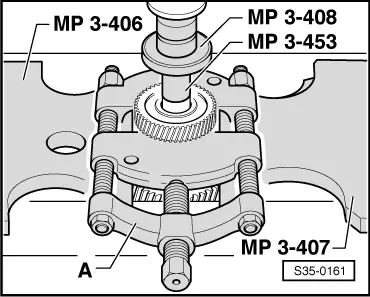

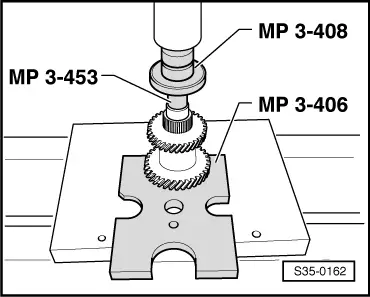

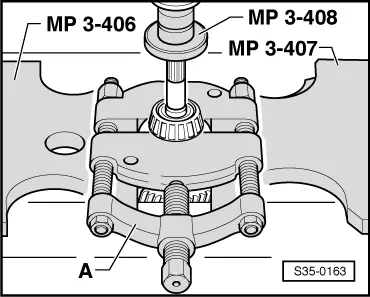

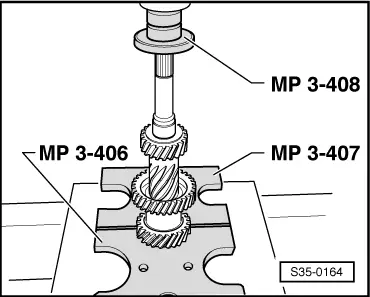

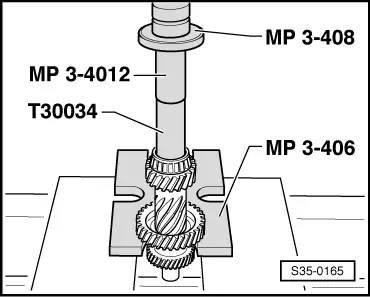

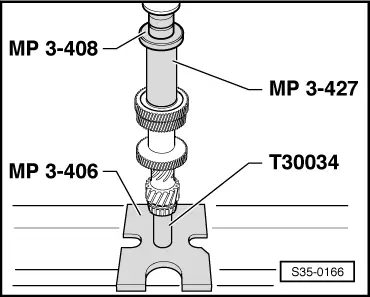

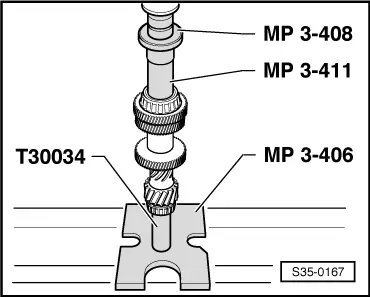

| Pressure plate -MP3-406 (VW 401)- |

| t

| Pressure plate -MP3-407 (VW 402)- |

| t

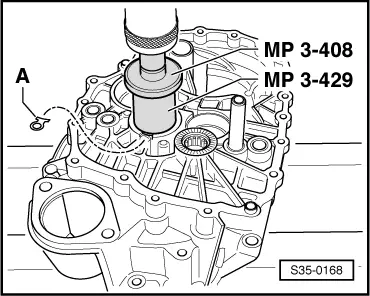

| Thrust piece -MP3-408 (VW 412)- |

| t

| Pressure plate -MP3-411 (VW 454)- |

| t

| Pressure washer -MP3-413 (VW 510)- |

| t

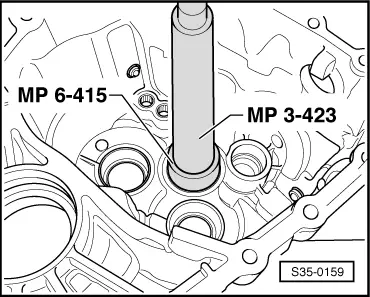

| Thrust piece -MP3-423 (VW 407)- |

| t

| Drift pin -MP3-426 (30-505)- |

| t

| Drive bushing -MP3-427 (40-21)- |

| t

| Pipe section -MP3-429 (20-10)- |

| t

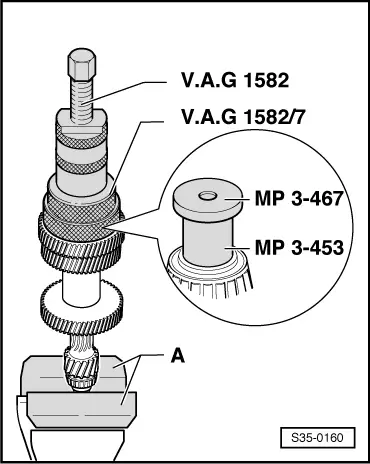

| Pressure plate -MP3-453 (VW 431)- |

| t

| Thrust plate -MP3-467 (40-105)- |

| t

| Pipe section -MP3-4012 (VW 416B)- |

| t

| Pressure plate -MP3-4014 (VW 432)- |

| t

| Gearbox mount -MP3-501- |

| t

| Washer -MP6-415 (3260)- |

| t

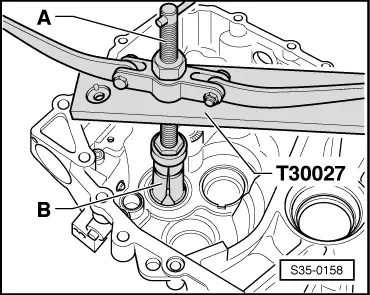

| Retaining plate -T30027 (VW 801)- |

| t

| Knock-in bushing -T30034 (41-501)- |

| t

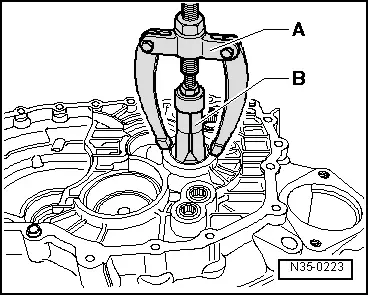

| Tapered-roller bearing extractor -V.A.G 1582- |

| t

| Interior extractor 46...58 mm, e.g. -Kukko 21/7- |

| t

| Separating device 22...115 mm, e.g. -Kukko 17/2- |

| t

| Countersupport, e.g. -Kukko 22/2 - |

|

|

|

Note

Note