Fabia Mk1

Note

Note

|

| 1 - | Top toothed belt guard |

| 2 - | Toothed belt |

| q | removing and installing, tensioning → Chapter |

| 3 - | 10 Nm |

| 4 - | 20 Nm + torque a further 45° (1/8 turn) |

| 5 - | 100 Nm |

| 6 - | Camshaft sprocket |

| 7 - | Hub |

| q | with rotor |

| q | to release and tighten use the counterholder -T10051- |

| q | to remove the extractor -T10052- use |

| q | removing and installing → Chapter |

| 8 - | Rear toothed belt guard |

| 9 - | Grommet |

| q | replace if damaged |

| 10 - | Camshaft position sensor -G40- |

| q | for removing, take the grommet → Chapter (Pos. 9) out of the rear toothed belt guard |

| 11 - | Cylinder head bolt |

| q | replace |

| q | pay attention to sequence for loosening and tightening → Chapter |

| q | if bearing caps of the camshaft are removed, insert special bases into the cylinder block before installing the cylinder head bolts → Chapter |

| 12 - | Bolt, 10 Nm |

| q | for engine cover |

| 13 - | Cylinder head cover |

| q | before fitting on, thoroughly clean sealing surface with a clean cloth |

| 14 - | to charge air pipe at the rear |

| 15 - | 10 Nm |

| q | tighten all bolts first of all by hand |

| q | Tighten crosswise from the inside outwards |

| 16 - | Pressure control valve |

| 17 - | Oil filler inlet |

| 18 - | Screw cap |

| 19 - | Sealing sleeve |

| q | replace if damaged |

| 20 - | Support |

| q | with fuel line |

| 21 - | Gasket for cylinder head cover |

| q | replace if damaged |

| 22 - | 20 Nm |

| 23 - | Lifting eye |

| 24 - | The unit injector |

| q | removing and installing → Chapter |

| 25 - | Mixing tube |

| q | inserted into cylinder head |

| q | pull out with hook |

| 26 - | Central plug connection |

| q | for pump-nozzle unit |

| 27 - | To the brake servo unit |

| 28 - | Tandem pump |

| q | for fuel and vacuum supply |

| q | removing and installing → Chapter |

| q | check → Chapter |

| 29 - | Intake hose |

| q | from fuel filter → Chapter |

| q | white marking |

| q | check for firm seating |

| q | secure with spring strap clamps |

| 30 - | Return-flow hose |

| q | for engine with identification characters AMF: to the fuel filter → Chapter |

| q | for engine with identification characters BNM, BNV: to the combination valve → Chapter |

| q | blue marking |

| q | check for firm seating |

| q | secure with spring strap clamps |

| 31 - | Gasket |

| q | replace |

| 32 - | Support |

| 33 - | Hexagon taper nut |

| 34 - | Cylinder head |

| q | removing and installing → Chapter |

| q | after replacing fill entire system with fresh coolant |

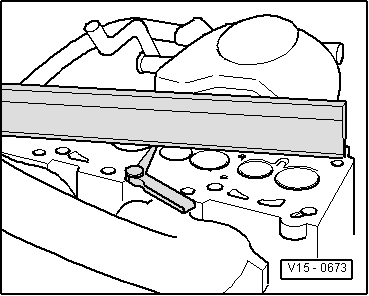

| q | Inspecting the cylinder head for distortion → Fig. |

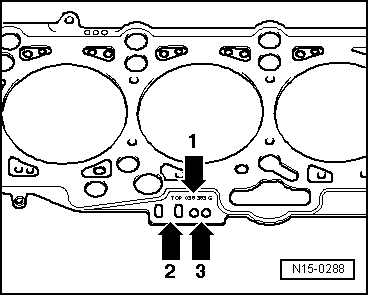

| 35 - | Cylinder head gasket |

| q | replace |

| q | Pay attention to the marking → Fig. |

| 36 - | Glow plug |

| q | 15 Nm |

| 37 - | Tensioning pulley |

| 38 - | 20 Nm + torque a further 45° (1/8 turn) |

Note

Note

|

|