| –

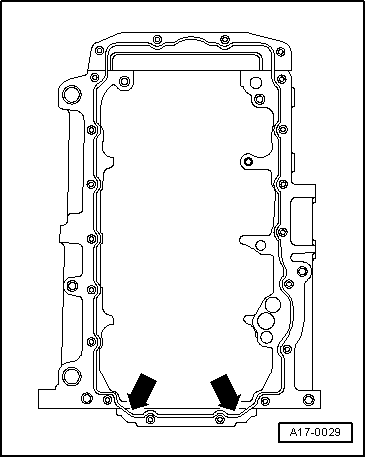

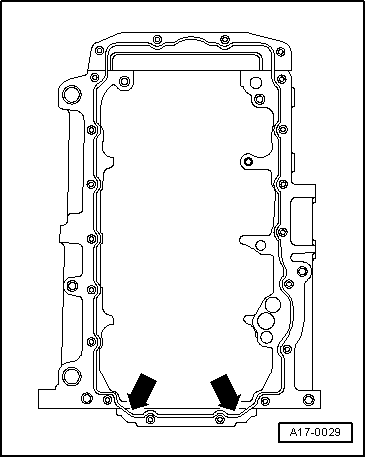

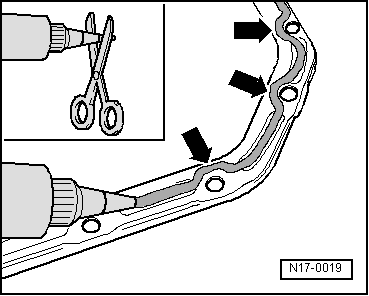

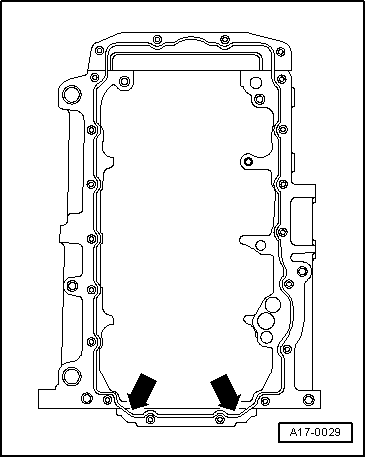

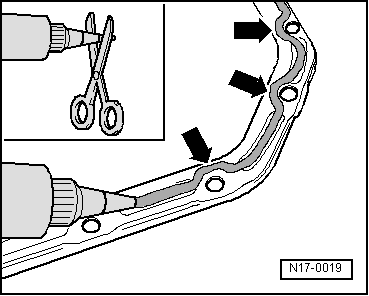

| Apply silicone sealant to the clean sealing surface of the oil pan, as shown in the illustration. (The diagram shows the sealant bead on the cylinderblock.) |

| –

| Fit oil pan immediately and lightly tighten all oil pan screws. |

| –

| Tighten the oil pan bolts to 15 Nm. |

| –

| Install the bolts on the oil pan/gearbox to a torque of 45 Nm. |

Note | t

| After installing the oil pan, allow the sealant to dry for about 30 minutes. Only then may engine oil be filled in. |

| t

| The oil pan must be aligned with the cylinder block. |

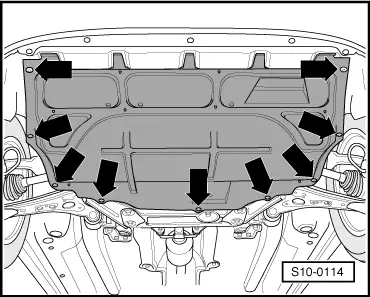

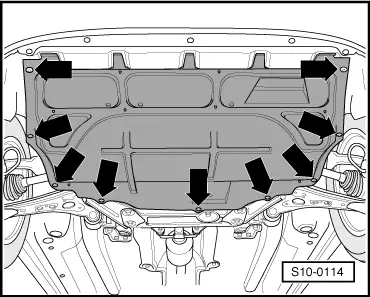

| Further installation occurs in a similar way in reverse order to removal. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note