| –

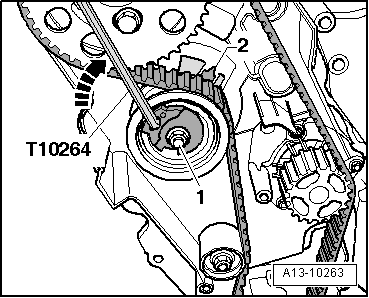

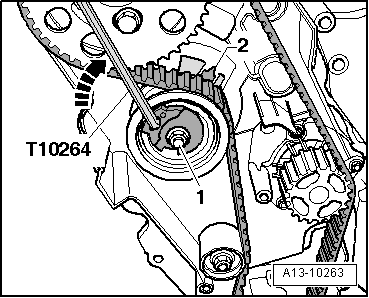

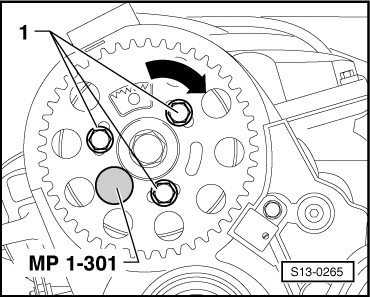

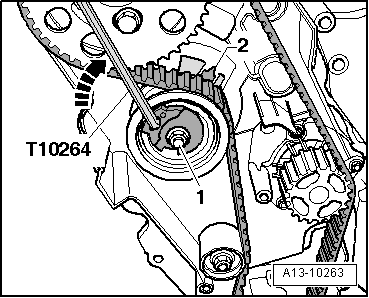

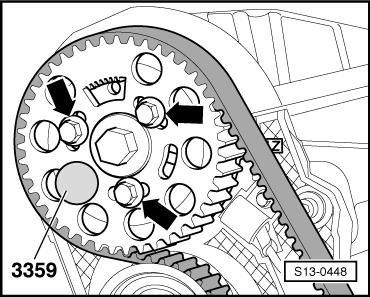

| Turn the eccentric of the tensioning pulley with offset screwdriver -T10264- clockwise -arrow- in such a way until the pointer -2- stands in the centre of the base plate in the gap. |

Note | Ensure that the fixing nut of the tensioning pulley does not turn. |

| –

| Hold the tensioning pulley in this position and tighten the fixing nut -1- of the tensioning pulley to 20 Nm + torque a further + 45° (1/8 turn). |

Note | When tightening the fixing nut, the pointer -arrow- turns max. 5 mm to the right from the gap of the base plate. This position must not be corrected, because the toothed belt settles when running-in. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note