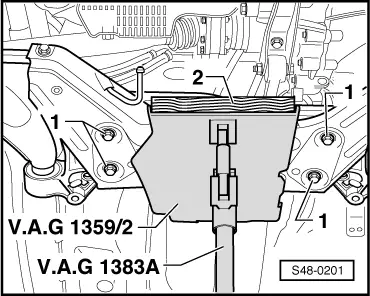

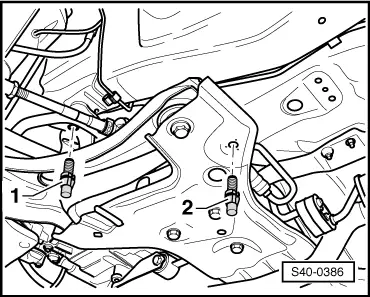

| Power-steering gear to assembly carrier | 50 Nm + 90° |

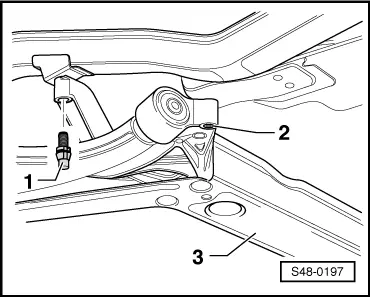

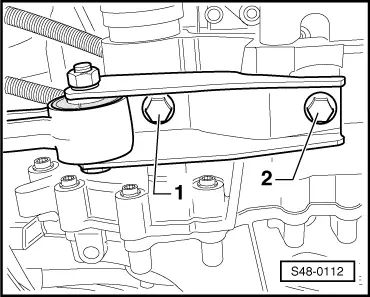

| Assembly carrier to body | 70 Nm + 90° |

| Support to body | 20 Nm + 90° |

| Pendulum support to gearbox | 30 Nm + 90° |

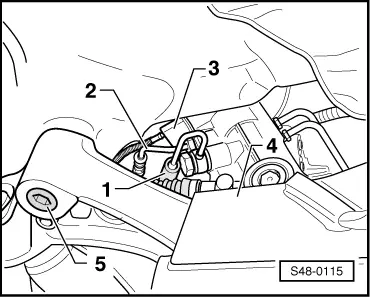

| Track rod end/track rod to steering arm | 20 Nm + 90° |

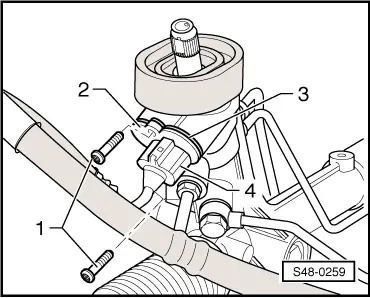

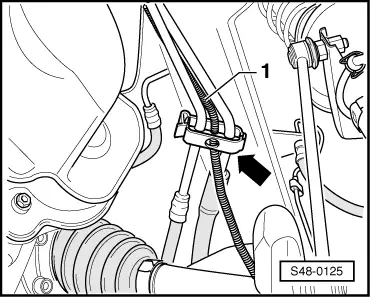

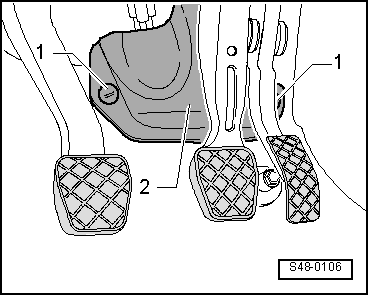

| power-assisted steering sensor -G250- to power-assisted steering gear TRW | 6 Nm |

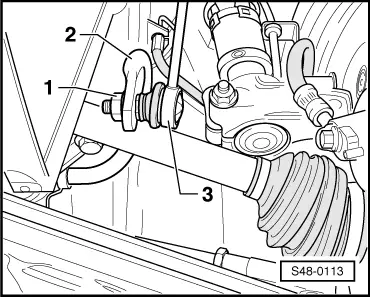

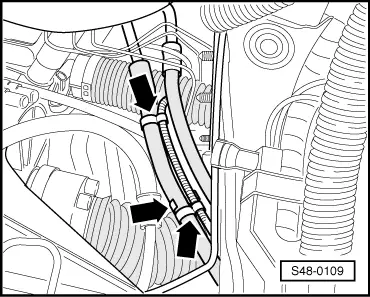

| Hollow screw for pressure line to power steering gear TRW (M14x1.5) | 35 Nm |

| Pipe screw for return line to power steering gear TRW (M16x1.5) | 30 Nm |

| Coupling rod to anti-roll bar | 40 Nm |

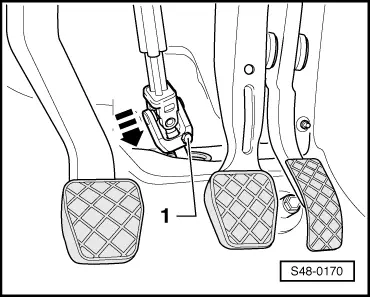

| Universal joint of the steering column to power-steering gear | 20 Nm + 90° |

| Wheel bolts | → Chapter |

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution