Fabia Mk2

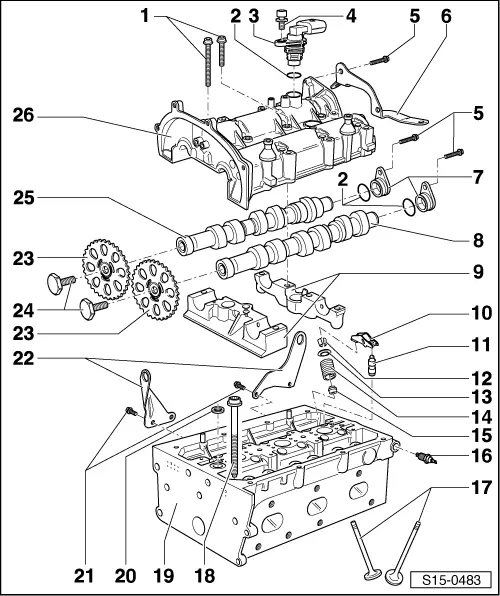

| Summary of components |

Note

Note| t | Removing and installing intake manifold → Chapter. |

| t | Removing and installing exhaust manifold → Chapter. |

| t | removing and installing coolant regulator housing → Chapter. |

| t | If the cylinder head is replaced, the system must be completely filled with fresh coolant. |

| 1 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| 2 - | O-ring |

| q | replace if damaged |

| 3 - | Camshaft position sensor -G163- |

| 4 - | 8 Nm |

| 5 - | 10 Nm |

| 6 - | Support |

| q | for wiring loom |

| 7 - | Cap |

| 8 - | Exhaust camshaft |

| q | Inspecting axial play → Chapter |

| 9 - | Bearing cap for camshaft |

| q | When installing pay attention to the smooth operation of the camshaft |

| q | Inspecting axial play → Chapter |

| 10 - | Roller rocker arm |

| q | do not get them confused with each other. |

| q | inspect roller bearings |

| q | oil contact surface |

| q | for installing, clip onto hydraulic supporting element with locking clips |

| 11 - | Supporting element |

| q | do not get them confused with each other. |

| q | with hydraulic valve clearance compensation |

| q | oil contact surface |

| 12 - | Valve collets |

| 13 - | Valve spring retainer |

| 14 - | Valve spring |

| q | removing and installing → Chapter, replace the valve stem seal |

| q | replace springs as a set only |

| 15 - | Valve stem seal |

| q | replace → Chapter |

| 16 - | 0.045 MPa (0.45 bar) oil pressure switch -F1-, 25 Nm |

| q | check → Chapter |

| 17 - | Valve |

| q | do not rework, only grinding in is permissible |

| q | Valve dimensions → Chapter |

| 18 - | Cylinder head bolt |

| q | replace |

| q | observe the mounting instructions and sequence for loosening and tightening → Chapter |

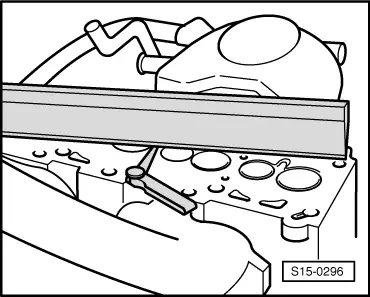

| 19 - | Cylinder head |

| q | inspecting valve guides → Chapter |

| q | check for distortion → Fig. |

| 20 - | Sealing ring |

| q | Clean strainer if dirty |

| 21 - | 20 Nm |

| 22 - | Lifting eye |

| 23 - | Camshaft sprocket |

| 24 - | 50 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | Interlock the camshafts with counterholder -MP1-216 (3036)- for removing and installing → Chapter |

| 25 - | Inlet camshaft |

| 26 - | Cylinder head cover |

| q | sealing surfaces must not be reworked. |

| q | removing and installing → Chapter, removing and installing the camshaft |