| –

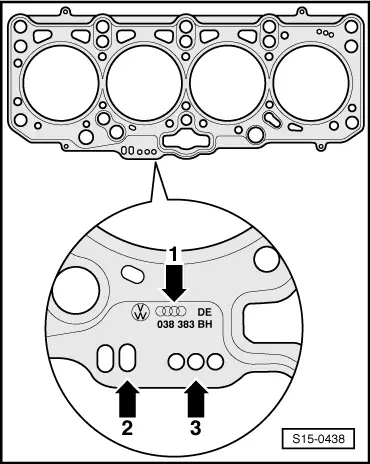

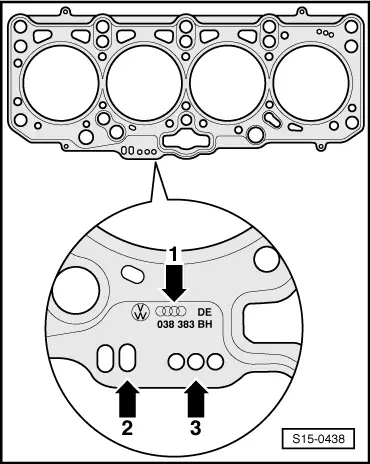

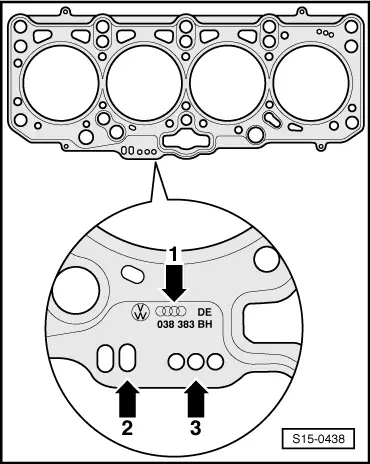

| Pay attention to the identification of the cylinder head seal. |

| t

| Part number = -arrow 1- |

| t

| Control code = -arrow 2- (ignore) |

Note | t

| If the cylinder head gasket or cylinder head were replaced, install a new cylinder head gasket with the same identification marking. |

| t

| If parts of the crankshaft drive were replaced, then the new cylinder head gasket must be redefined by measuring the protrusion of the piston in TDC. |

| –

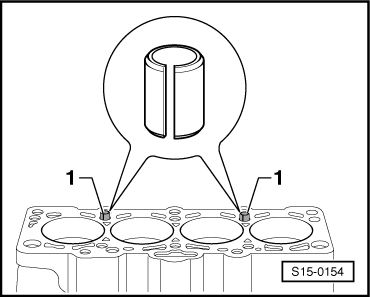

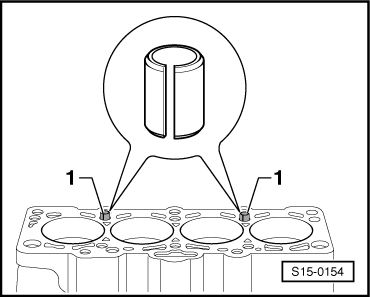

| Fit on cylinder head gasket. |

| –

| Position cylinder head, insert all cylinder head bolts and tighten by hand. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note