| Special tools and workshop equipment required |

| t

| Removal tool for inner lining of the door panel -MP8-602/1- |

| t

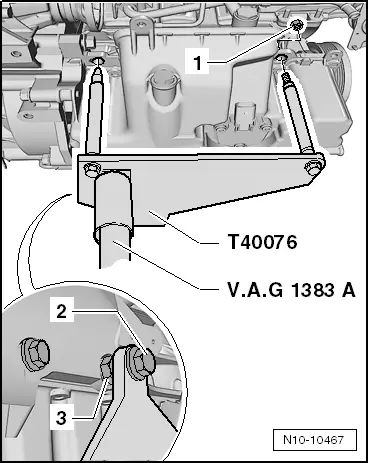

| Engine/gearbox jack, e.g. -V.A.G 1383 A- |

| t

| Catch pan, e.g. -VAS 6208- |

| t

| Double ladder, e. g. -VAS 5085- |

| t

| Pliers for spring strap clamps |

Note | t

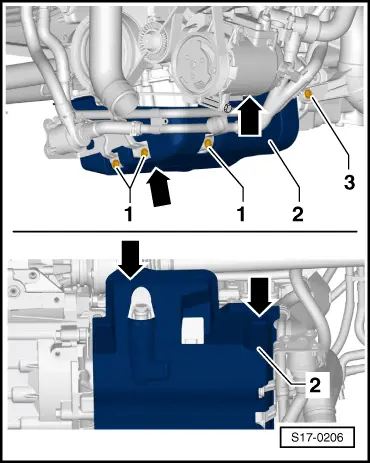

| The engine is removed downwards together with the gearbox. |

| t

| All cable straps that have been loosened or cut open when the engine was removed must be attached again in the same location when the engine is installed again. |

| t

| Leave the ignition key in the ignition lock so that the steering lock does not click into place. |

| t

| Collect drained coolant in a clean container for proper disposal or reuse. |

WARNING | When undertaking all installation work, particularly in the engine compartment because of its cramped construction, please observe the following: |

| t

| Lay lines of all kinds in such a way that the original line guide is re-established. |

| t

| Ensure that there is adequate free access to all moving or hot components. |

|

| Observe all safety measures and notes for assembly work on the fuel supply and injection system, at the charge air system and observe as well the rules for cleanliness → Chapter. |

| Observe the instructions for the fuel hose in the engine compartment → Chapter. |

| –

| If present, take the adapter for the anti-theft wheel bolts out of the luggage compartment. |

| –

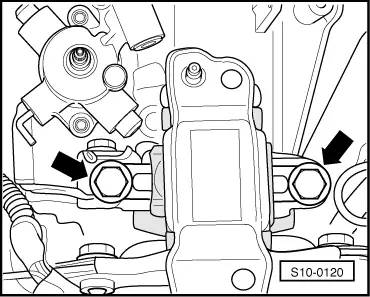

| Only slacken the nut of the right drive shaft. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution