| Removing and installing camshafts |

| Special tools and workshop equipment required |

| t

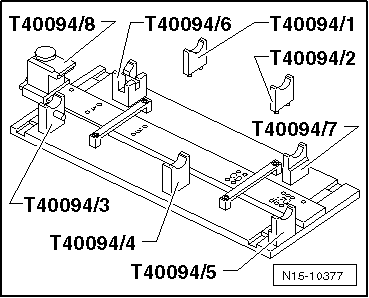

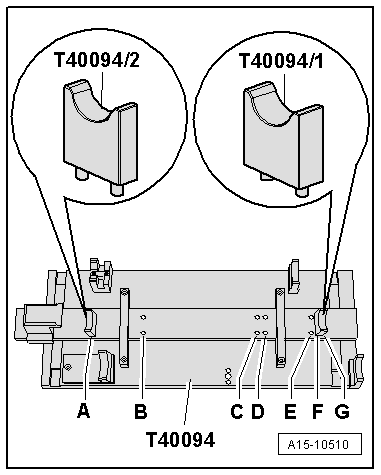

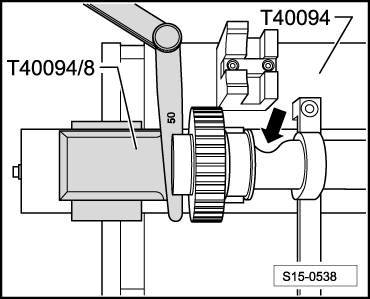

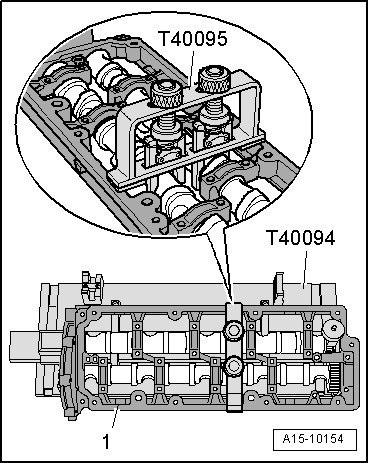

| Camshaft-insertion tool -T40094- |

| t

| Camshaft-insertion tool -T40095- |

| t

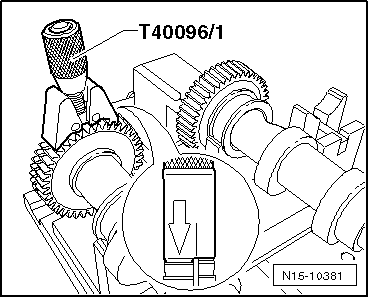

| Tensioning tool -T40096/1- |

| t

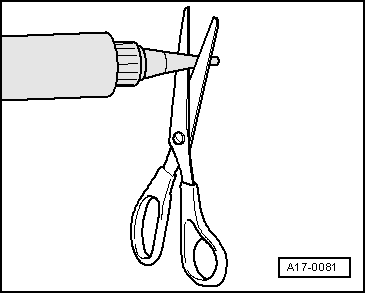

| Silicone sealant -D 176 501 A1- |

| t

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning and degreasing agent, e.g. -D 009 401 04- |

| t

| Protective goggles and gloves |

| –

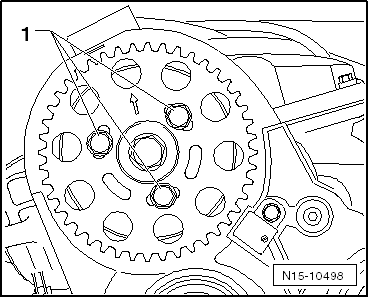

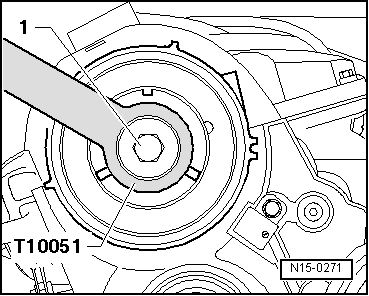

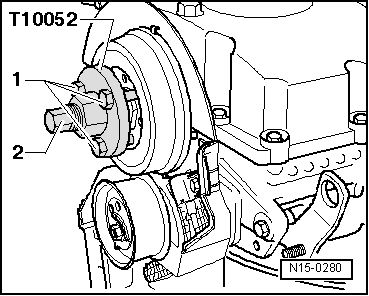

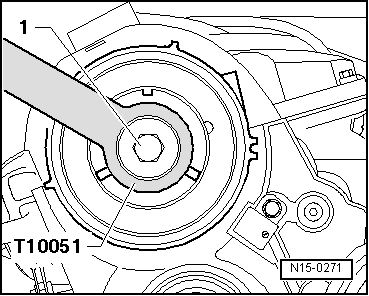

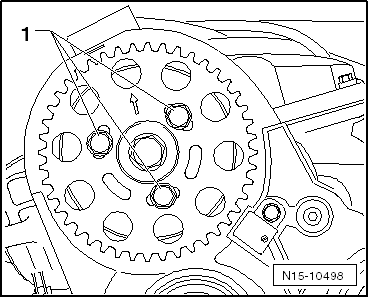

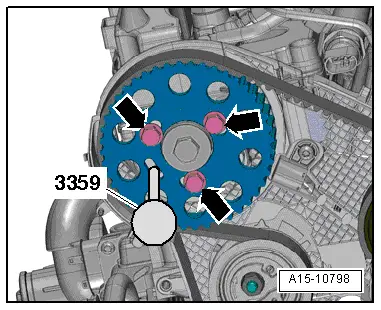

| Pull toothed belt off camshaft sprocket and from toothed belt gear on the high pressure pump → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution