| –

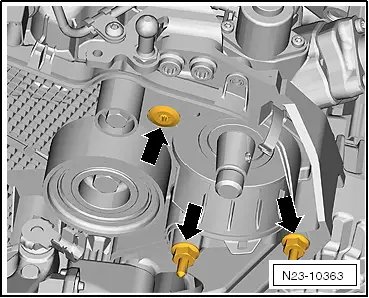

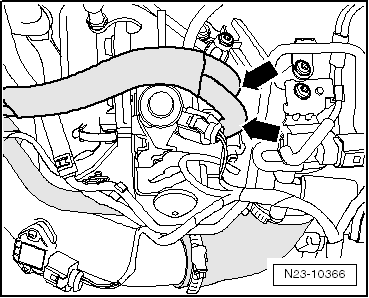

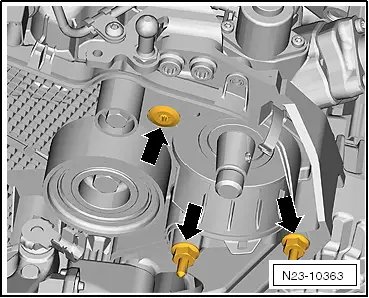

| Release the fixing screws -arrows- of the high pressure pump. |

| –

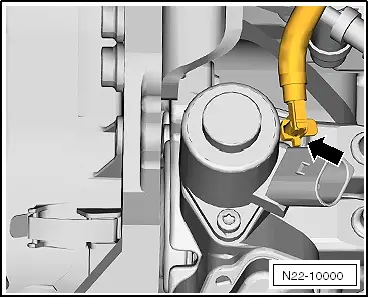

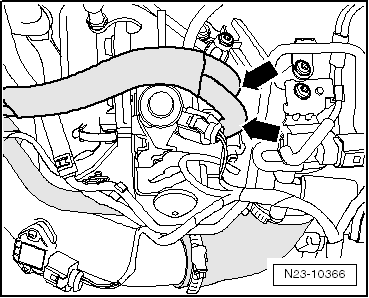

| Remove the high pressure pump. |

Caution | Risk of damage to the high pressure pump through running dry. |

| If the high pressure pump is removed or replaced, the initial fuel filling of the high pressure pump must be carried out before the first engine start. For this purpose, connect vehicle diagnosis, measurement and information system -VAS 505x- and carry out the targeted function „filling/bleeding the high pressure pump and the fuel system“. During this function, the fuel pump is actuated for 180 seconds. |

|

Note | t

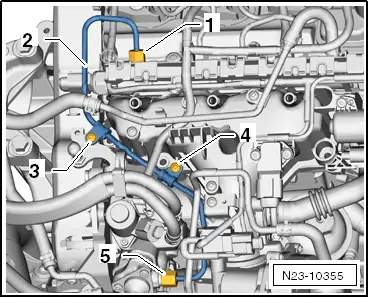

| When installing the high pressure pump, ensure that no dirt penetrates the fuel system. |

| t

| Only remove the screw plug immediately before installing the fuel lines. |

| Installation occurs in reverse order for removal, while paying attention to the following: |

| t

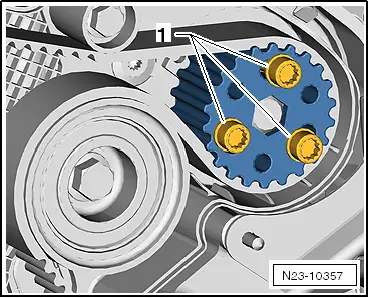

| The screws for the high pressure pump must be replaced. |

| t

| Tightening torques of fuel system → Chapter. |

| t

| Tightening torques of toothed belt drive → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution