| –

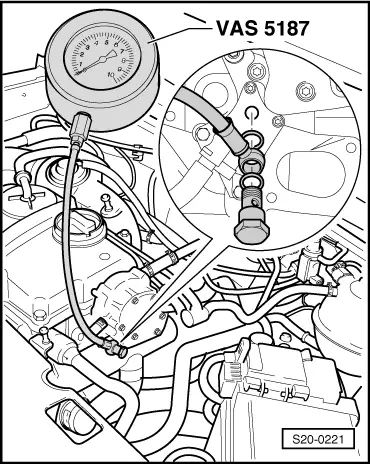

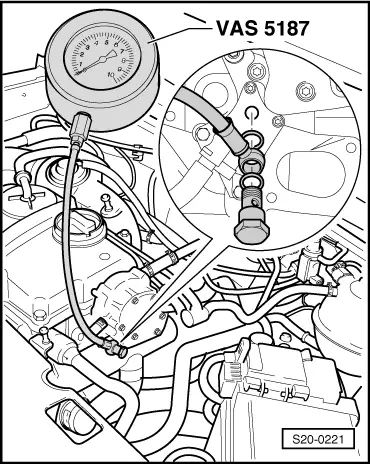

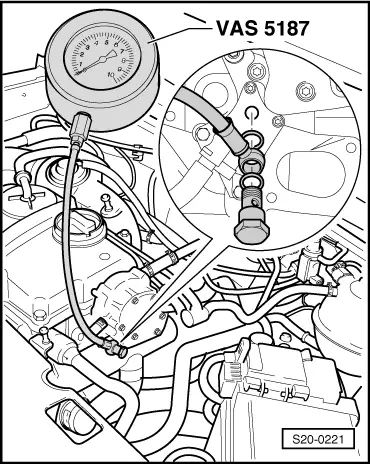

| Connect pressure gauge appliance -VAS 5187- as shown. |

| –

| Start engine and run in idle. |

| –

| Note the pressure shown on the pressure gauge. Specified value: min. 0,35 MPa (3,5 bar). |

| –

| Engine speed must increase to 4000 rpm. |

| –

| Note the pressure shown on the pressure gauge. Specified value: min. 0.75 MPa (7.5 bar). |

| If the nominal value of min. 0.75 MPa (7.5 bar) is not reached: |

| –

| Close return-flow line between tandem pump and fuel filter with hose clamp -MP 7-602 (3094)-. |

| –

| Start engine and engine speed must increase to 4000 rpm. |

| –

| Note the pressure shown on the pressure gauge. Specified value: min. 0.75 MPa (7.5 bar). |

| If the specified value is reached: |

| Pressure loss at the unit injectors. |

| –

| Replace O-rings for unit injectors. |

| If the specified value is still not reached: |

Note | After removing the pressure gauge appliance tighten the plug to 25 Nm. Always replace the gasket ring. |

Note | After re-installing an already used tandem pump e.g. after changing or repairing the cylinder head and/or after changing an engine without component parts, the tandem pump must be absolutely checked for internal tightness between fuel and oil part. In case of leakage fuel and oil can be mixed, which can cause an engine damage. |

| Special tools and workshop equipment required |

| t

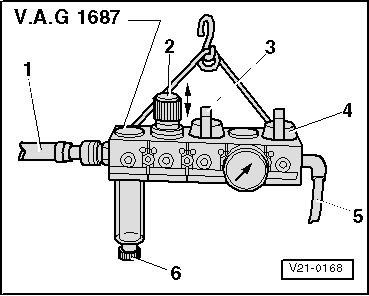

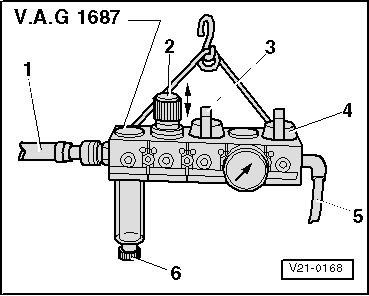

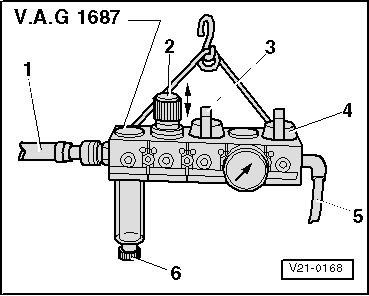

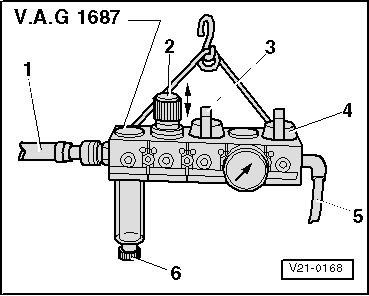

| Tester, e.g. -V.A.G 1687- |

| –

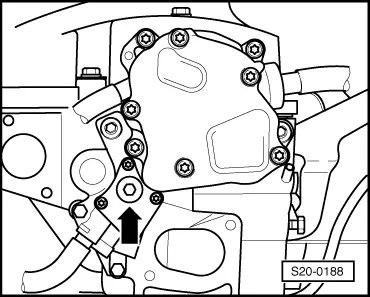

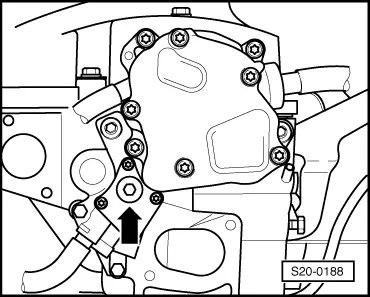

| Disconnect the fuel intake hose (white marking) and the fuel return-flow hose (blue marking) from the tandem pump. |

| –

| Close fuel return-flow connection at tandem pump with a dummy plug. Secure the dummy plug with a spring strap clamp. |

| Prepare tester e.g. -V.A.G 1687- as follows: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note