| (Fabia II, Roomster, Rapid) |

| Special tools and workshop equipment required |

| t

| Grease -G 000 100- for manual gearbox |

| l

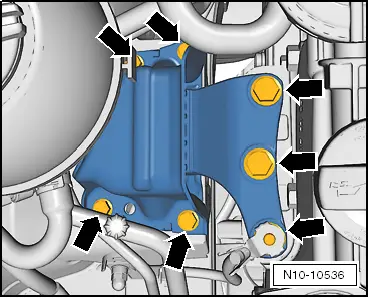

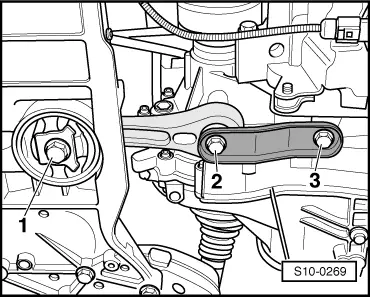

| Fit engine and gearbox using engine mount to the engine/gearbox jack. |

| Installation is performed in the reverse order, pay attention to the following points: |

Note | t

| Observe all safety measures and notes for assembly work on the fuel supply and injection system, at the charge air system and observe as well the rules for cleanliness → Chapter. |

| t

| When undertaking assembly replace self-locking nuts and screws which have been tightened to a torquing angle. |

| t

| Always replace gasket rings and seals. |

| t

| All cable straps should be fastened again in the same place when installing. |

Caution | When undertaking all installation work, particularly in the engine compartment due to its cramped construction, please observe the following: |

| t

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling fluid and refrigerant, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| In order to avoid damage to the cables, ensure that there is adequate free access to all moving or hot components. |

|

Note | t

| Clean the serration of the drive shaft and if the clutch disc has been used clean the hub serration, remove corrosion and only apply a very thin layer of grease -G 000 100- on the serration. Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. Always remove excess grease. |

| –

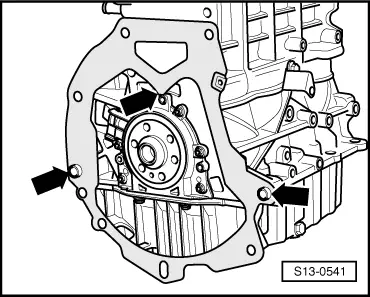

| Check whether the dowel sleeves for centering the engine/gearbox are present in the cylinder block; insert if necessary. |

|

|

|

Note

Note Note

Note

Note

Note

Caution

Caution