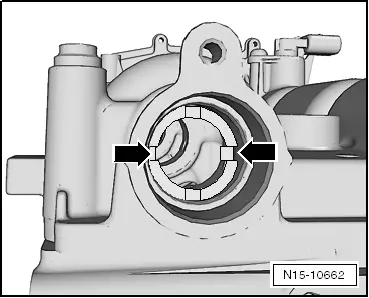

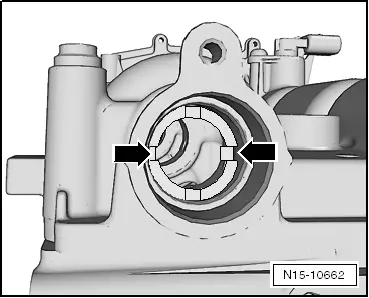

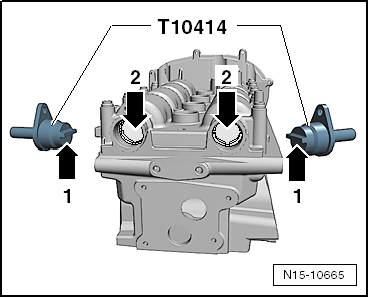

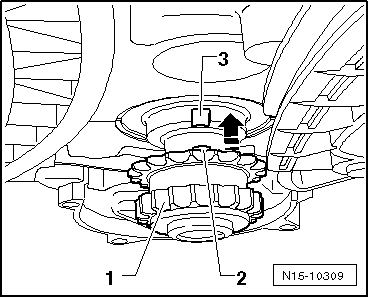

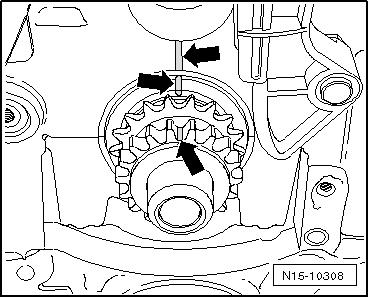

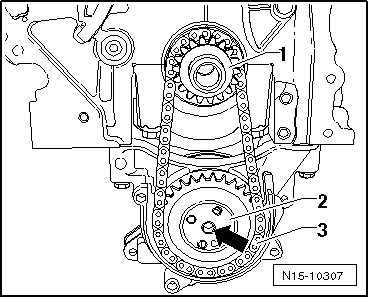

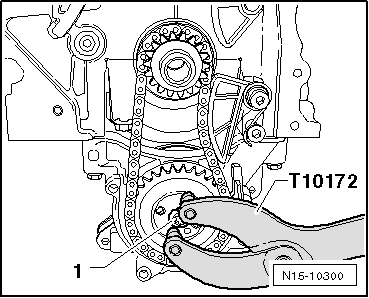

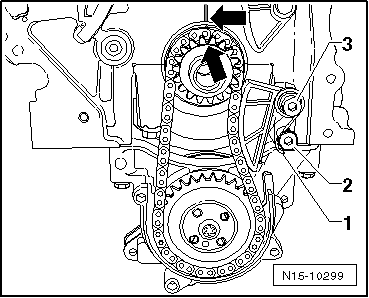

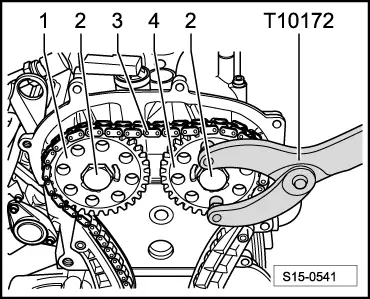

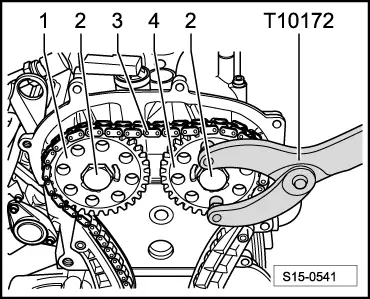

| The holes -arrows- in the camshafts must be positioned as shown, if necessary rotate the crankshaft a further revolution (360°). |

Note | t

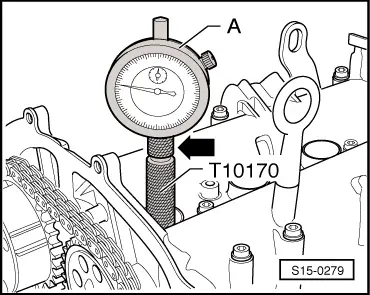

| If the crankshaft was turned more than 0.01 mm past the top dead centre, the crankshaft must once again be turned approx 45° in the opposite direction of rotation of the engine. Then position crankshaft in direction of rotation of engine on TDC for cylinder 1. |

| t

| Permissible deviation from TDC for cylinder 1: ± 0.01 mm. |

| –

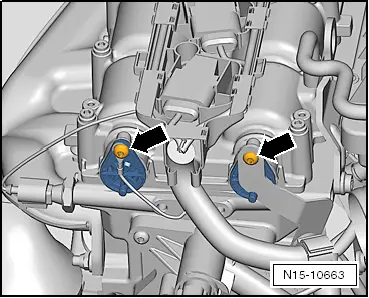

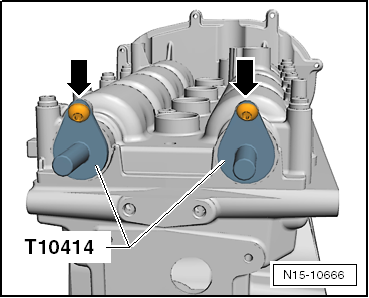

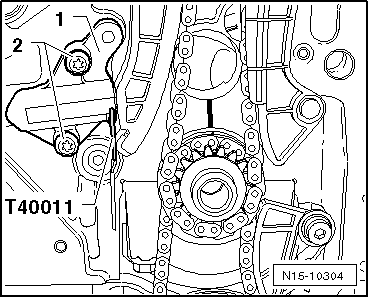

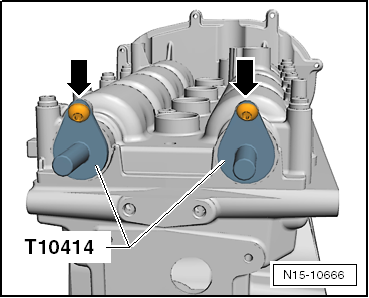

| Insert the fixing bolt -T10414- up to the stop into the camshaft openings. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution