Fabia Mk2

|

| 1 - | 40 Nm + torque a further 90° (1/4 turn) |

| q | Left-hand thread |

| q | replace |

| 2 - | 50 Nm + torque a further 90° (1/4 turn) |

| 3 - | Camshaft adjuster |

| q | for inlet valves |

| q | with chain sprocket |

| q | Observe the fitting position of the timing chain |

| q | must not be disassembled |

| q | removing and installing → Chapter |

| 4 - | Sprocket |

| q | for exhaust camshaft |

| q | Observe the fitting position of the timing chain |

| 5 - | Camshaft adjustment valve 1 -N205- |

| 6 - | 10 Nm |

| 7 - | O-ring |

| q | replace |

| q | oil before the assembly |

| 8 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | tighten from inside to outside |

| 9 - | Camshaft housing |

| q | removing and installing → Chapter |

| 10 - | Roller rocker arm |

| q | inspect roller bearings of roller for smooth operation |

| q | oil contact surfaces |

| q | for installing, clip onto the supporting element and secure with locking clip |

| 11 - | Valve collets |

| 12 - | Supporting element |

| q | do not interchange |

| q | with hydraulic valve clearance compensation |

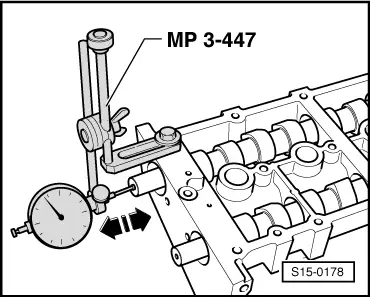

| q | before installing check axial play of the camshaft → Fig. |

| q | oil contact surfaces |

| 13 - | Valve spring retainer |

| 14 - | Valve spring |

| q | removing and installing → Chapter |

| 15 - | Valve stem seal |

| q | replace → Chapter |

| 16 - | Valve guide |

| q | not to be replaced |

| q | check → Chapter |

| 17 - | Cylinder head |

| q | reworking valve seats → Chapter |

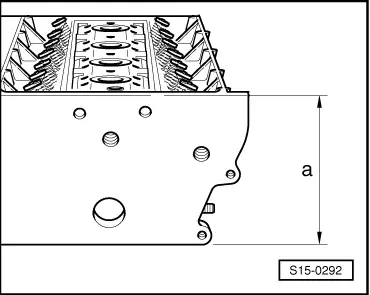

| q | reworking sealing surface → Fig. |

| 18 - | Valves |

| q | do not rework, only grinding in with grinding paste is permissible |

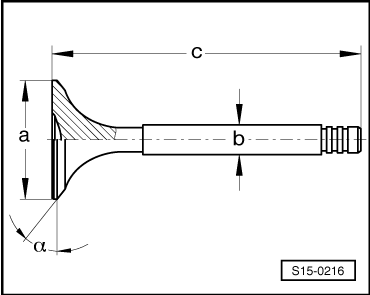

| q | Valve dimensions → Fig. |

| 19 - | Support |

| 20 - | Screw cap |

| q | for hole of inlet camshaft |

| 21 - | Screw cap |

| q | for hole of exhaust camshaft |

| 22 - | Exhaust camshaft |

| q | do not mix up with inlet camshaft |

| q | Inspecting axial play → Fig. |

| q | moisten with oil before installing (also axial bearing collar) |

| 23 - | Inlet camshaft |

| q | do not mix up with exhaust camshaft |

| q | Inspecting axial play → Fig. |

| q | moisten with oil before installing (also axial bearing collar) |

| 24 - | Guide bushing |

Note

Note

|

|

Note

Note

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 29,5 | 26,0 |

| Ø b | mm | 5,973 | 5,953 |

| c | mm | 100,9 | 100,5 |

| α | ∠° | 45 | 45 |