| Special tools and workshop equipment required |

| t

| Double ladder, e. g. -VAS 5085- |

| t

| Catch pan, e.g. -VAS 6208- |

| t

| Pliers for spring strap clamps |

| l

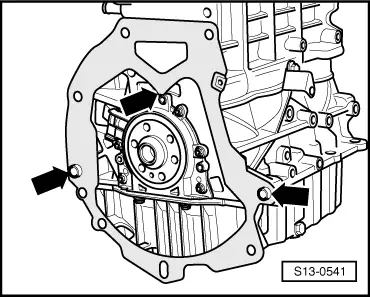

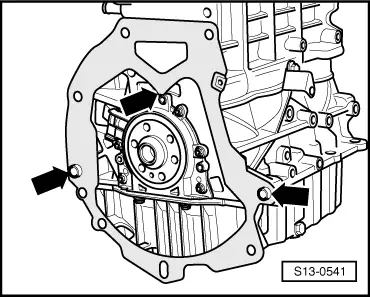

| Fit engine and gearbox using engine mount -T10416- to the engine/gearbox jack -V.A.G 1383 A-. |

| Installation is carried out in the reverse order. Pay attention to the following: |

Caution | When undertaking all assembly work, particularly in the engine compartment due to its cramped construction, please observe the following: |

| t

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, the active charcoal container-unit, cooling fluid and refrigerant, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| In order to avoid damage to the cables, ensure that there is adequate free access to all moving or hot components. |

|

Note | t

| All cable straps should be fastened again in the same place when installing. |

| t

| Replace the self-locking nuts and screws when undertaking assembly work. |

| t

| Replace screws which have been tightened to a torquing angle as well as gasket rings and seals. |

| Observe all safety measures and notes for assembly work on the fuel system, on the injection and ignition system and the charge air system as well as rules for cleanliness → Chapter. |

| For vehicles with manual gearbox |

| –

| Clean the serration of the drive shaft and if the clutch disc has been used clean the hub serration, remove corrosion and only apply a very thin layer of grease -G 000 100- to the serration of the drive shaft. Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. Always remove excess grease. |

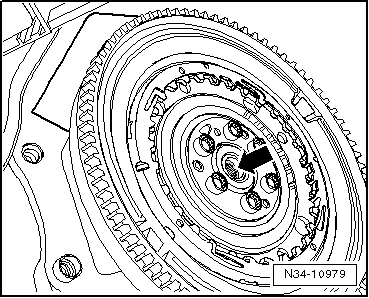

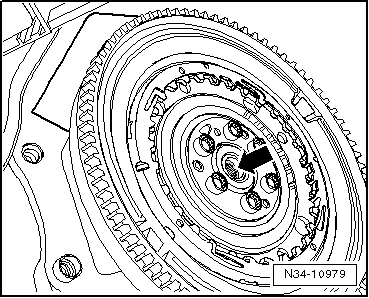

| For models with automatic gearbox |

|

|

|

Note

Note

Note

Note