| Removing and installing camshaft housing |

| Special tools and workshop equipment required |

| t

| Counterholder -T30004 (3415)- with replaceable bolts -T30004/1 - |

| t

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning and degreasing agent, e.g. -D 009 401 04- |

| t

| Protective goggles and gloves |

Note | t

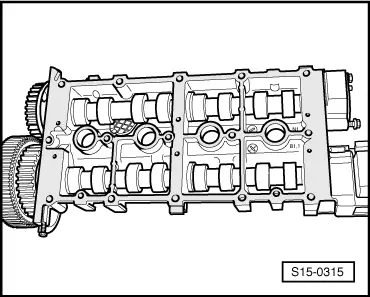

| The camshafts are located in the camshaft housing. This is why the camshaft housing must only be removed once the two toothed belts have been removed. |

| t

| Do not rework the sealing surface of the camshaft housing. |

| t

| Removing and installing camshafts → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note