| –

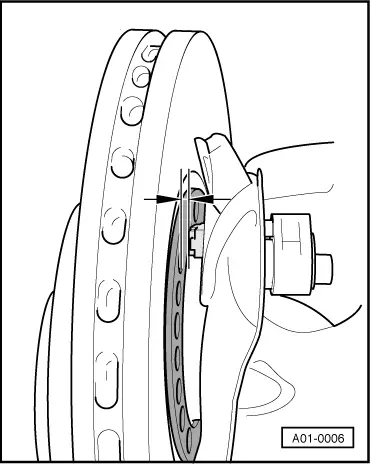

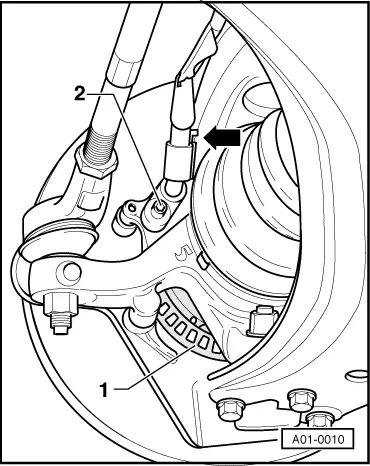

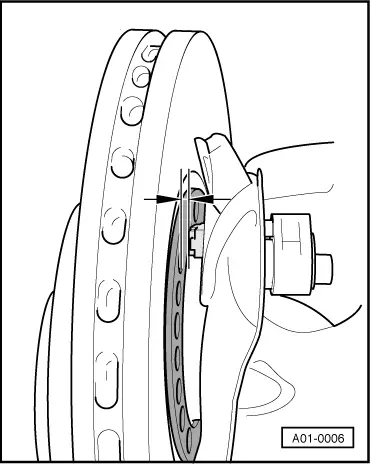

| Turn the wheel hub and check the distance between the pulse rotor and the wheel speed sensor for evenness (axial run-out tolerance). In this test, the wheel bearing play must be accounted for. |

| l

| The axial run-out tolerance of the pulse rotor is 0.3 mm. |

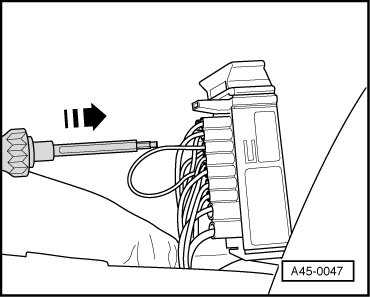

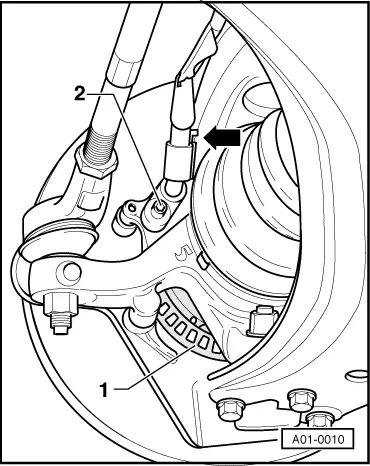

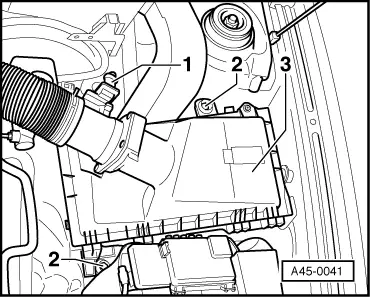

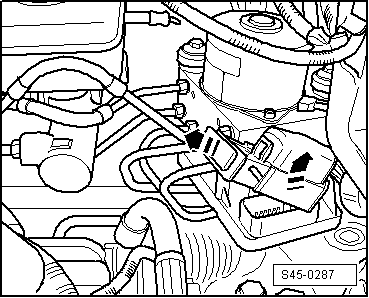

| Removing and installing the wheel speed sensor cables |

Note | t

| It is prohibited to repair shielded leads of the ABS system. |

| t

| Before disconnecting the battery determine the code of radio sets fitted with anti-theft coding. |

| t

| After connecting the battery, perform the following: |

| –

| on vehicles with radio encoding, carry out the coding, |

| –

| initialise power windows on vehicles fitted with power windows → BookletOctavia |

Note | The following 2 work steps do not apply to the 1.6 ltr./55 kW engine: |

|

|

|

Note

Note Note

Note

Note

Note