Octavia Mk1

Note

Note

|

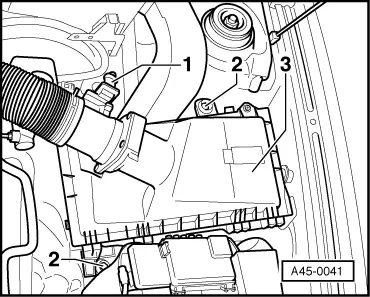

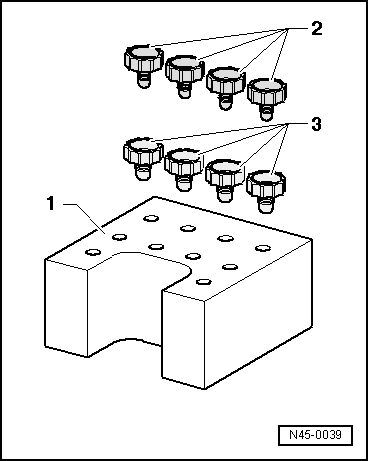

| 1 - | Hydraulic control unit |

| t | the hydraulic pump -V64-, the hydraulic unit -N55- and the ABS control unit -J104- form the hydraulic control unit. |

| t | the hydraulic control unit must be removed and installed as a whole unit |

| t | repairing → Chapter |

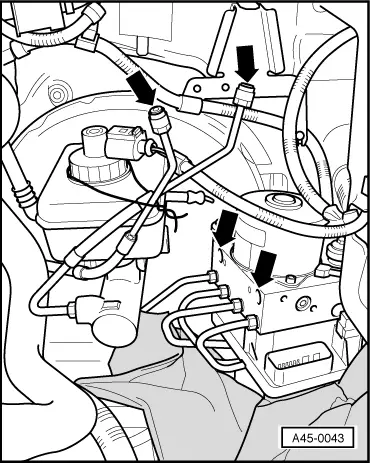

| 2 - | Brake line, 14 Nm |

| t | between the master brake cylinder/floating piston circuit and ABS hydraulic unit |

| 3 - | Brake line, 14 Nm |

| t | ABS hydraulic unit to front left brake caliper |

| 4 - | Brake line, 14 Nm |

| t | ABS hydraulic unit to wheel cylinder/rear right brake caliper |

| 5 - | Brake line, 14 Nm |

| t | ABS hydraulic unit to wheel cylinder/rear left brake caliper |

| 6 - | Brake line, 14 Nm |

| t | ABS hydraulic unit to front right brake caliper |

| 7 - | Brake line, 14 Nm |

| t | between master brake cylinder/push rod piston circuit and hydraulic unit |

| 8 - | Multi-pin connector/ABS control unit |

| t | 25-pin |

| t | do not disconnect the plug connector before the self-diagnosis is complete, switch off the ignition before disconnecting the plug connector |

| 9 - | Self-locking nut, 20 Nm |

| 10 - | Support |

| 11 - | Dowel screw, 8 Nm |

| 12 - | Cap nut, 25 Nm |

Note

Note

Note

Note

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|