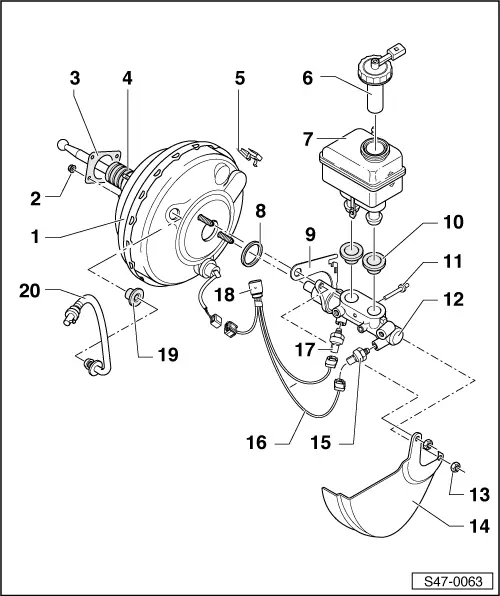

Octavia Mk1

| 1 - | Brake servo unit |

| t | check → Chapter |

| t | removing and installing - LHD vehicles → Chapter |

| t | removing and installing - RHD vehicles → Chapter |

| t | if there are faults replace completely |

| t | separate from brake pedal → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| t | on petrol engines the required negative pressure is drawn from the induction pipe |

| t | vehicles using a diesel engine are fitted with a vacuum pump for generating a low pressure |

| t | Non-return valve (in the vacuum hose of the vacuum pump) |

| Functional test |

| – | It must be possible to blow through the valve in the -direction of the arrow-. |

| – | Against the direction of the arrow the valve must be closed. |

| 2 - | Self-locking nut 28 Nm |

| t | replace |

| 3 - | Gasket |

| t | for brake servo unit |

| t | between brake servo unit and bulkhead |

| 4 - | Bellows |

| t | pay attention to correct position, risk of suction noises |

| 5 - | Holder |

| t | is attached to the edge of the brake servo unit |

| t | serves for the support of the plug -Pos. 18- |

| 6 - | Screw cap |

| t | with integrated brake fluid level warning contact -F34- |

| 7 - | Brake fluid reservoir |

| t | locked with lateral catches in the retaining pin |

| 8 - | Sealing ring |

| t | replace |

| 9 - | Retaining bracket |

| t | for fixing the wiring loom -Pos. 16- |

| 10 - | Plugs |

| t | moisten with brake fluid and press in expansion reservoir |

| 11 - | Retaining pin |

| t | fit through the master brake cylinder |

| 12 - | Master brake cylinder |

| t | cannot be repaired, replace completely in the event of faults |

| t | Check tightness → Chapter |

| 13 - | Self-locking nut 20 Nm |

| t | replace |

| 14 - | Heat shield |

| t | only for vehicles with 74 kW, 92 kW and 110 kW engine |

| 15 - | Brake pressure sender -1--G201- |

| t | in the floating piston circuit |

| t | removing and installing → Chapter |

| 16 - | Wiring loom |

| 17 - | Brake pressure sender -2--G214- |

| t | in the push rod piston circuit |

| t | removing and installing → Chapter |

| 18 - | Connector |

| t | Connection wiring loom dash panel/engine compartment |

| 19 - | Plugs |

| 20 - | Vacuum hose |

| t | with non-return valve |

| t | insert in brake servo unit. |

Note

Note