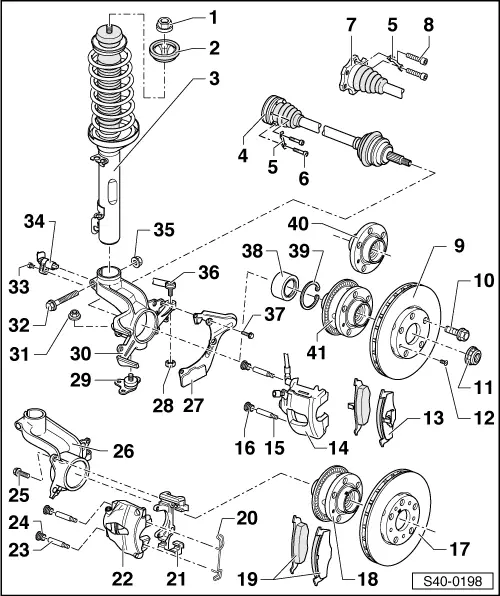

Octavia Mk1

| 1 - | Self-locking nut, 60 Nm |

| t | replace after each removal |

| 2 - | Stop |

| 3 - | Suspension strut |

| t | removing and installing → Chapter |

| t | repairing → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| 4 - | Drive shaft with inner CV joint |

| t | removing and installing → Chapter |

| t | repairing → Chapter |

| 5 - | Shim |

| 6 - | Fillister head screw with internal serrations |

| t | replace after each removal |

| t | initially tighten to 10 Nm and subsequently tighten crosswise to final torque: |

| M8 = 20 Nm + 180° |

| M10 = 50 Nm + 45° |

| t | Assignment → Electronic Catalogue of Original Parts |

| 7 - | Drive shaft with inner tripod joint |

| t | removing and installing → Chapter |

| t | repairing → Chapter |

| 8 - | Fillister head screw with internal serrations |

| t | replace after each removal |

| t | initially tighten to 10 Nm and subsequently tighten crosswise to final torque: |

| M8 = 20 Nm + 90° |

| M10 = 50 Nm + 45° |

| t | Assignment → Electronic Catalogue of Original Parts |

| 9 - | Brake disc (FS-III) |

| t | without marking for axial run-out |

| t | with a fixing hole for the wheel hub |

| t | Assignment → Electronic Catalogue of Original Parts |

| 10 - | Wheel screw, 120 Nm |

| 11 - | Self-locking twelve-point nut |

| t | slacken and tighten → Chapter |

| t | replace after each removal |

| 12 - | 4 Nm |

| 13 - | Brake discs (FS-III) |

| t | removing and installing → Chapter |

| 14 - | Brake caliper (FS-III) |

| Including for vehicles with engine up to 92 kW. |

| t | do not release brake hose when working on the front wheel suspension |

| t | tie up with wire or anything similar |

| t | repairing → Chapter |

| 15 - | Guide bolt (FS-III), 30 Nm |

| t | removing and installing → Chapter |

| 16 - | Cap (FS-III) |

| 17 - | Brake disc (FN 3) |

| t | with marking for maximum axial run-out |

| t | with 5 fixing holes for the wheel hub |

| t | removing and installing → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| 18 - | Wheel hub with pulse rotor for wheel speed sensor |

| t | with marking for minimum axial run-out |

| t | only on vehicles with ABS |

| t | pressing out → Chapter |

| t | installing → Chapter |

| t | Pull off the inner ring of the bearing → Chapter |

| t | Check axial run-out of pulse rotor → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| 19 - | Brake discs (FN-3) |

| t | removing and installing → Chapter |

| 20 - | Retaining spring (FN-3) |

| 21 - | Brake carrier (FN-3) |

| 22 - | Brake caliper (FN-3) |

| Including for vehicles with engine as of 96 kW. |

| t | do not release brake hose when working on the front wheel suspension |

| t | tie up with wire or anything similar |

| t | Removing and installing brake pads → Chapter |

| t | repairing → Chapter |

| 23 - | Guide bolt (FN-3), 30 Nm |

| t | removing and installing → Chapter |

| 24 - | Cap (FN-3) |

| 25 - | Screw with securing collar (FN-3), 124 Nm |

| t | Clean ribbing on the underside |

| 26 - | Wheel-bearing housing |

| Including for vehicles with engine as of 96 kW. |

| t | removing and installing → Chapter |

| t | repairing → Chapter |

| t | before pressing in the wheel bearing, coat the entire wheel bearing seat in the wheel bearing housing evenly with -G 052 723 A2- |

| 27 - | Cover plate |

| 28 - | Self-locking nut, 50 Nm |

| t | replace after each removal |

| 29 - | Steering joint |

| t | check → Chapter |

| t | Inspect rubber bellows for damage, if necessary replace |

| t | removing and installing → Chapter |

| 30 - | Wheel-bearing housing |

| Including for vehicles with engine up to 92 kW. |

| t | removing and installing → Chapter |

| t | repairing → Chapter |

| t | before pressing in the wheel bearing, coat the entire wheel bearing seat in the wheel bearing housing evenly with -G 052 723 A2- |

| 31 - | Self-locking nut, 20 Nm + 90° |

| t | replace after each removal |

| 32 - | Screw |

| t | replace after each removal |

| 33 - | 8 Nm |

| 34 - | ABS wheel speed sensor |

| t | only on vehicles with ABS |

| t | insert with solid lubricant paste -G 000 650- (e.g. Wolfrakote Top Paste) |

| 35 - | Self-locking nut |

| t | up to 05.98: 50 Nm + 90° |

| t | as of 06.98: 60 Nm + 90° |

| t | replace after each removal |

| 36 - | Track rod with track rod end |

| t | removing and installing → Chapter |

| 37 - | 10 Nm |

| 38 - | Wheel bearing |

| t | press out → Chapter |

| t | replace, is damaged when pressing out |

| t | installing → Chapter |

| t | The spare part is only delivered as a set „wheel bearing with mounting parts“ (Pos. 11, 39, 38, 28, 31 and 35) |

| 39 - | Circlip |

| t | pay attention to correct position → Chapter |

| t | replace after each removal |

| 40 - | Wheel hub without pulse rotor |

| t | only on vehicles without ABS |

| t | Assignment → Electronic Catalogue of Original Parts |

| 41 - | Wheel hub with pulse rotor for wheel speed sensor |

| t | without marking for minimum axial run-out |

| t | only on vehicles with ABS |

| t | press out → Chapter |

| t | installing → Chapter |

| t | Pull off the inner ring of the bearing → Chapter |

| t | Check axial run-out of pulse rotor → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

Note

Note